The world of steel pipes can be overwhelming. With terms like "seam" and "seamless," it's easy to be confused. Understanding these differences is crucial for making informed decisions. Seam pipes, also known as welded pipes, use steel sheets or strips and are commonly used for transporting water and gas. Seamless pipes are made from round steel and feature no welded joint, making them strong and versatile.

While both types of pipes have their places in industry, knowing which to choose depends on factors like pressure requirements, usage, and cost considerations.

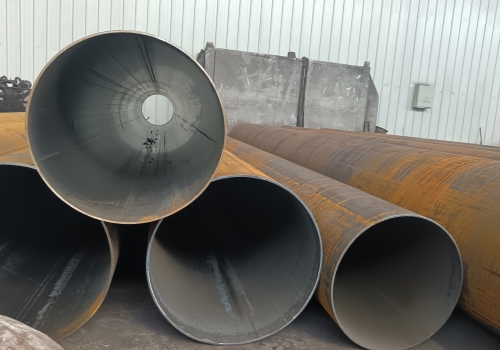

Seam pipes, often referred to as welded pipes, have been essential in various applications. Their ubiquity is seen in construction where transporting fluids is required. Seam pipes are crafted by welding steel sheets or strips. They range in nominal size from DN15 to DN150 and are used for low-pressure applications such as water and gas transportation.

Beyond just transport, galvanized versions of these pipes serve different purposes on construction sites. This versatility makes seam pipes a staple in many industries.

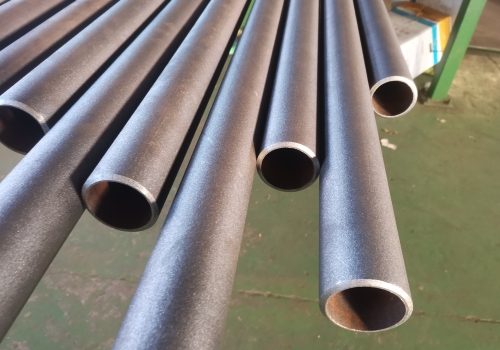

Seamless pipes offer unique advantages and fulfill specific roles thanks to their construction method. Seamless pipes are made by piercing round steel and are distinguished by their lack of weld seams. This seamlessness affords them higher pressure capacities, often exceeding 7 MPa, making them ideal for rigorous applications like petrochemical transport.

These pipes come in a variety of shapes and sizes, including thick or thin walls, catering to specific needs across industries like automotive and aviation.

Understanding the key differences helps in selecting the right pipe for the job. Here's a simple breakdown:

| Aspect | Seam Pipe | Seamless Pipe |

|---|---|---|

| Construction | Welded | Perforated / Seamless |

| Pressure | Above 1.6 MPa | Above 7 MPa |

| Use | Low-pressure fluid transport | Structural and transport |

| Complexity | Simple welding process | Complex rolling process |

| Cost | More affordable | More expensive |

| These differences highlight that while seam pipes fulfill general needs efficiently and economically, seamless pipes provide strength and adaptability in demanding environments. |

Choosing between seam and seamless pipes boils down to specific needs. Seam pipes are cost-effective for basic needs, while seamless pipes offer durability for high-pressure demands.