Seamless tubes are long steel products with a hollow cross-section and no seams. Due to their superior strength and durability, they are widely used for transporting fluids such as oil, natural gas, water, and even certain solid materials. The manufacturing process of seamless tubes ensures high structural integrity, making them ideal for demanding industrial applications.

In this article, we explore the key methods of seamless tube production, the different types available, and their diverse applications.

The two primary methods for seamless tube production are:

This method involves piercing a solid billet using skewed rolls, then elongating it through a rolling mill.

· Advantages: High production speed, cost-effective for carbon steel and low-alloy steel tubes.

· Limitations: Requires high workability of the billet.

Here, a piercing machine punches a hole into the billet or ingot, followed by extrusion to form the tube.

· Advantages: Suitable for high-strength alloy steel tubes.

· Limitations: Slower than the Mandrel Mill process.

Both methods involve heating the billet, producing hot-rolled tubes. For enhanced precision and mechanical properties, further cold processing may be applied:

· Cold Drawing: Pulling the tube through a die to reduce diameter and increase length.

· Cold Rolling: Using modified rolling mills for improved surface finish and dimensional accuracy.

Seamless tubes are classified based on production methods, shapes, materials, and applications:

· Hot-rolled tubes

· Cold-rolled tubes

· Cold-drawn tubes

· Extruded tubes

· Round tubes (most common)

· Special-shaped tubes (square, rectangular, oval, hexagonal, triangular, and more)

· Carbon steel tubes

· Low-alloy steel tubes

· High-quality carbon steel tubes

· Alloy steel tubes

· Stainless steel tubes

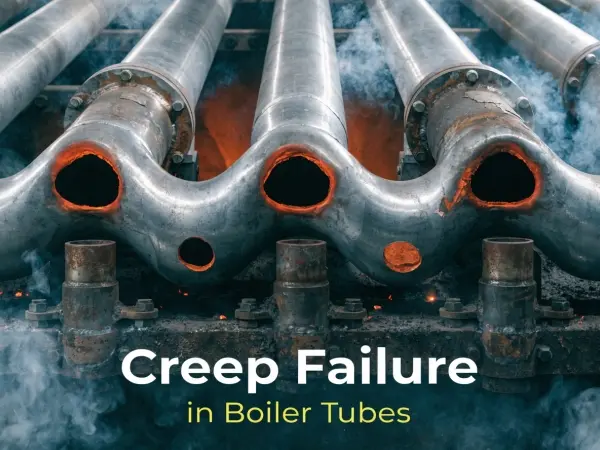

· Boiler tubes (high-temperature resistance)

· Geological tubes (drilling and exploration)

· Oil pipes (petroleum and gas transportation)

Seamless tube production ensures:

✔ Higher strength (no welded seams)

✔ Better pressure resistance (ideal for high-stress environments)

✔ Superior corrosion resistance (especially in stainless steel variants)

✔ Precise dimensions (critical for mechanical and structural applications)

Understanding seamless tube production helps industries select the right type for their needs. Whether for oil pipelines, construction, or high-pressure boilers, seamless tubes offer unmatched reliability.

Looking for high-quality seamless tubes? Contact us today to find the best solution for your project!