Selecting the right stainless steel seamless pipe supplier is a critical decision that impacts product performance, safety, and long-term costs. Whether you're sourcing pipes for oil & gas, chemical processing, power plants, or construction, partnering with a reliable stainless steel seamless pipe supplier ensures durability, compliance, and efficiency.

This guide will help you evaluate suppliers based on key factors such as certifications, manufacturing processes, material quality, and customer support—so you can make an informed choice.

A trustworthy stainless steel seamless pipe supplier must adhere to internationally recognized standards, including:

Key Certifications to Look For:

· ASTM A312 / ASTM A213 – Standard specification for seamless stainless steel pipes.

· ASME B36.19M – Covers dimensions and tolerances for stainless steel pipes.

· ISO 9001:2015 – Ensures quality management system compliance.

· PED 2014/68/EU (Pressure Equipment Directive) – Essential for European market suppliers.

· NACE MR0175 / MR0103 – Critical for sour service (H2S-resistant) applications.

Why It Matters:

Certifications prove that the supplier follows strict quality control measures, reducing risks of defects and failures.

A top-tier stainless steel seamless pipe supplier should have advanced production capabilities and rigorous testing protocols.

· Cold Drawing & Cold Rolling – Ensures precise dimensions and smooth surface finishes.

· Hot Extrusion – Used for thicker-walled pipes and high-temperature applications.

· Solution Annealing – Enhances corrosion resistance by removing internal stresses.

· Hydrostatic Testing – Checks for leaks and pressure resistance.

· Ultrasonic Testing (UT) & Eddy Current Testing (ECT) – Detects internal and surface defects.

· Positive Material Identification (PMI) – Verifies alloy composition using XRF analyzers.

· Mechanical Testing – Confirms tensile strength, hardness, and elongation properties.

Tip: Ask for Mill Test Certificates (MTCs) to verify material properties before purchasing.

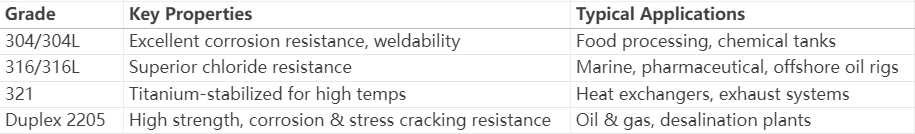

Different industries require specific stainless steel grades for optimal performance.

Pro Tip: Ensure your supplier offers the right grade for your operating environment (e.g., high temperature, acidic conditions).

A reputable stainless steel seamless pipe supplier will have:

✅ Positive reviews on Google, Alibaba, or industry forums

✅ Long-term clients in sectors like oil & gas, petrochemicals, or power generation

✅ Case studies or project references

Red Flags to Avoid:

❌ No verifiable certifications

❌ Unusually low prices (may indicate inferior materials)

❌ Lack of transparency in testing reports

While cost is important, the cheapest option isn’t always the best. Consider:

✔ Competitive pricing (compare multiple quotes)

✔ Reliable lead times (avoid delays that disrupt projects)

✔ Shipping & logistics support (global suppliers should handle export documentation)

Negotiation Tip: Bulk orders often qualify for discounts—discuss long-term supply agreements.

A dependable supplier should offer:

✦ Technical support (help with material selection, welding advice)

✦ Warranty against manufacturing defects

✦ Replacement or refund policies

Finding a high-quality stainless steel seamless pipe supplier requires due diligence in certifications, manufacturing processes, material testing, and customer service. By following these guidelines, you can minimize risks and ensure you receive pipes that meet industry standards and performance expectations.

Looking for a trusted supplier? Centerway Steel provides ASTM/ASME-certified stainless steel seamless pipes with full traceability and global shipping. Contact Us Today for a quote!