Steel seamless pipes are essential in industries such as oil and gas, chemical processing, and water supply due to their high strength, corrosion resistance, and ability to withstand extreme pressure. To maximize their performance and lifespan, proper treatment methods must be applied during fabrication and installation. Below, we explore the key processes involved in preparing and maintaining steel seamless pipes for optimal functionality.

Before any treatment begins, the steel seamless pipe must be cut to the required length. This is typically done using:

· Metal saws – Ideal for clean, burr-free cuts.

· Abrasive saws (cut-off wheels) – Efficient for thick-walled pipes.

· Flame cutting (oxy-fuel torches) – Used for large-diameter pipes but requires protective measures.

Safety Precautions:

· Use fire-resistant barriers to catch sparks and molten metal.

· Cool the cutting area with water to prevent heat distortion.

· Ensure the pipe’s plastic coating (if present) is not damaged during cutting.

Proper cutting ensures smooth edges, reducing the need for excessive grinding and improving weld quality.

After cutting, the pipe ends must be smoothed using an angle grinder to:

· Remove sharp edges and burrs that could weaken welds.

· Prepare the surface for coating or welding by ensuring a clean, even finish.

· Prevent plastic coating (if applied) from melting during welding.

Best Practices:

· Use fine-grit grinding discs for a polished finish.

· Inspect the pipe end for cracks or imperfections before proceeding.

This step is crucial for ensuring strong, leak-proof joints in steel seamless pipe systems.

Many steel seamless pipes are coated with plastic (such as polyethylene or epoxy) to enhance corrosion resistance. The coating process involves:

· Use an oxygen-C2H2 torch to heat the pipe’s exterior until the inner plastic layer softens.

· Maintain a temperature between 180°C – 220°C (356°F – 428°F) for optimal adhesion.

· Sprinkle or spray plastic powder evenly over the heated area.

· Ensure full coverage, especially beyond the flange’s water-stop line.

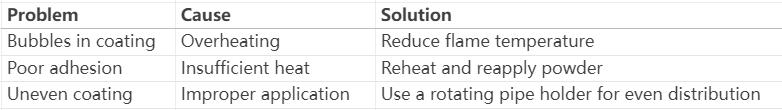

Common Issues & Solutions:

A well-applied plastic coating prevents rust and extends the service life of steel seamless pipes.

Once the pipe is cut, ground, and coated, it is ready for installation. The connection process includes:

· Align the pipe and flange precisely before welding.

· Use TIG or MIG welding for high-strength joints.

· Avoid overheating to prevent damage to the plastic coating.

· Place a rubber gasket between flanges to prevent leaks.

· Tighten bolts in a crisscross pattern for uniform pressure.

· Perform a pressure test to ensure no leaks are present.

Proper installation prevents future failures in steel seamless pipe networks.

To further enhance durability, consider:

· Galvanization – Zinc coating for extra rust resistance.

· Cathodic protection – Electrochemical corrosion prevention.

· Internal lining – For pipes carrying corrosive fluids.

From precise cutting and grinding to plastic coating and secure connections, each treatment step plays a vital role in maintaining the integrity of steel seamless pipes. By following these best practices, industries can ensure:

✔ Higher corrosion resistance

✔ Stronger, leak-proof joints

✔ Longer service life

For demanding applications in oil, gas, and chemical industries, properly treated steel seamless pipes remain the most reliable choice.

By implementing these techniques, engineers and fabricators can optimize performance and reduce maintenance costs in piping systems.

Final Tip: Regular inspections and maintenance further enhance the durability of steel seamless pipes, ensuring safe and efficient operations for years to come.