Choosing the right material for a Hydraulic Cylinder Pipe is critical for system reliability, performance, and safety. In high-pressure hydraulic systems, the pipe must withstand mechanical stress, resist corrosion, and maintain precise tolerances. Selecting the proper material ensures optimal performance, reduces maintenance costs, and extends the service life of the hydraulic system.

A Hydraulic Cylinder Pipe is the core structural component of a hydraulic cylinder, housing the piston and enabling smooth fluid movement under high pressure. The pipe’s material affects the cylinder’s durability, sealing performance, and overall reliability. Poor material selection can lead to premature failure, increased downtime, and costly repairs.

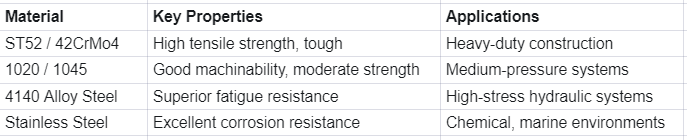

Hydraulic cylinder pipes operate under high pressures and cyclic loads. The material must have high tensile strength and fatigue resistance to prevent cracking or deformation. Common steel grades include:

· ST52 / 42CrMo4: Offers high tensile strength and toughness for heavy-duty applications.

· 1020 / 1045 Carbon Steel: Suitable for medium-pressure systems, with good machinability.

· 4140 Alloy Steel: Provides excellent fatigue resistance and durability for high-stress applications.

Corrosion can weaken the pipe wall and compromise sealing. Material options include:

· Stainless Steel (304 / 316): Ideal for chemical, marine, or high-moisture environments.

· Surface-treated Carbon Steel: Hard chrome plating or electroless nickel plating enhances wear and corrosion resistance.

Internal surface quality directly impacts piston seal wear and overall cylinder efficiency. Common finishing techniques include:

· Honing: Produces a precise, smooth surface to minimize friction.

· Skiving & Roller Burnishing: Efficient for mass production while maintaining tight tolerances.

The inner diameter, roundness, and straightness of a Hydraulic Cylinder Pipe are critical for performance. Materials that remain stable during machining and heat treatment processes maintain tight tolerances and reduce the risk of leakage or misalignment.

Balancing cost and performance is essential. High-end alloy steels and stainless steels offer superior properties but at a higher cost. Consider the application:

· Carbon steel with surface treatment is cost-effective for general industrial use.

· Alloy steel or stainless steel is recommended for high-pressure, high-stress, or corrosive environments.

Selecting the right material depends on understanding your system’s operational conditions:

· High-pressure systems: Use alloy steel or ST52 for strength and fatigue resistance.

· Corrosive environments: Stainless steel or coated carbon steel is preferred.

· Precision applications: Ensure a smooth honed surface and tight dimensional tolerances.

By considering these factors, engineers can maximize hydraulic efficiency and minimize maintenance costs.

For engineers and manufacturers looking for high-quality Hydraulic Cylinder Pipes, our seamless steel pipe products offer exceptional strength, precise tolerances, and excellent surface finish. Engineered to meet the demands of heavy-duty and high-pressure hydraulic systems, our pipes ensure durability, reliability, and superior performance in a wide range of industrial applications. Choosing our pipes helps reduce downtime, improve system efficiency, and extend the service life of your hydraulic cylinders.

Selecting the right material for a Hydraulic Cylinder Pipe requires balancing mechanical strength, corrosion resistance, surface finish, dimensional accuracy, and cost. Understanding your system’s operational requirements and environmental conditions ensures optimal performance, reliability, and longevity. Proper material choice reduces maintenance, prevents failures, and enhances overall hydraulic efficiency. With the right material and high-quality seamless steel pipes, your hydraulic systems can achieve maximum reliability and performance.