Quenching and tempering (Q&T) is a widely used heat treatment process to enhance the mechanical properties of steel, particularly strength and hardness. However, one common question arises: Does quench and tempered increase ductility?

While quenching alone can make steel brittle, the subsequent tempering process plays a crucial role in balancing strength and ductility. This article explores how Q&T affects ductility, the science behind it, and its practical implications in industries like oil & gas, automotive, and machinery.

Quenching involves rapidly cooling heated steel (usually austenitized) in water, oil, or air. This process forms martensite, an extremely hard but brittle microstructure.

· Effect on Ductility:

o Martensite has high strength but low ductility and toughness.

o Without tempering, quenched steel is prone to cracking under stress.

Tempering reheats quenched steel to a temperature below its critical point (typically 150–650°C or 300–1200°F). This step reduces brittleness while maintaining strength.

· How Tempering Improves Ductility:

o Transforms brittle martensite into tempered martensite or sorbite.

o Reduces internal stresses and increases toughness.

o Allows controlled trade-off between hardness and ductility.

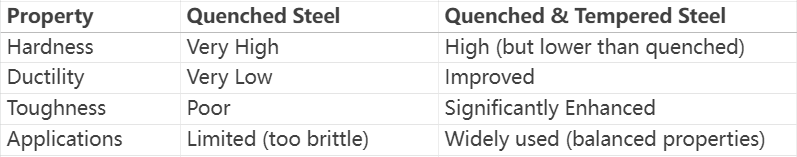

Conclusion: While quenching alone reduces ductility, tempering afterward restores it to a usable level while retaining much of the strength.

· Low Tempering (150–300°C): Retains high hardness but limited ductility.

· Medium Tempering (300–500°C): Best balance of strength and ductility (common in structural steels).

· High Tempering (500–650°C): Maximizes ductility and toughness but reduces hardness.

· Carbon Content: Higher carbon increases hardness but reduces ductility.

· Alloying Elements (Cr, Mo, Ni, V): Improve toughness and ductility retention.

· Slow cooling (furnace cooling) improves ductility.

· Rapid cooling (water/oil quenching) may reintroduce stresses.

· Drill pipes, casings, and tubing require high strength and ductility to withstand dynamic loads.

· Q&T steels like 4140 and 4340 are commonly used.

· Axles, crankshafts, and gears need fatigue resistance and impact toughness.

· Tempering ensures they don’t fail under cyclic stresses.

· Hydraulic cylinders, bearings, and high-stress fasteners benefit from Q&T’s balanced properties.

Yes, tempering after quenching significantly improves ductility compared to untempered martensite. While quenching alone maximizes hardness at the expense of ductility, tempering adjusts the microstructure to achieve a balanced combination of strength, toughness, and ductility.

For industries requiring high-performance steel, Q&T remains a critical process to ensure materials can endure stress without becoming brittle.

At Centerway, we're experts in producing precision quenched and tempered (Q&T) seamless steel tubes engineered to excel in even the most challenging industrial environments.

From high-pressure drill pipes that withstand extreme downhole conditions to durable hydraulic cylinders for heavy machinery and fatigue-resistant structural components, our Q&T seamless tubes deliver uncompromising performance when failure isn't an option.

Let's collaborate on your next project - contact our team today to discover how our engineered steel solutions can meet your specific requirements.