Precise steel pipe wall thickness control remains one of the most critical challenges in pipe manufacturing. Inconsistent steel pipe wall thickness can compromise structural integrity, cause regulatory non-compliance, and significantly increase material waste. This guide reveals 9 proven techniques to achieve optimal steel pipe wall thickness accuracy in seamless pipes, delivering superior quality while cutting production costs.

· Problem: Rapid temperature fluctuations cause uneven expansion, leading to thickness variations.

· Solution:

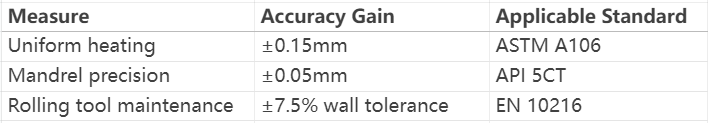

o Maintain stable heating/cooling rates (max ±30°C per adjustment).

o Use induction heating furnaces for precise temperature control.

· Impact: Reduces thermal stress-induced thickness deviations by 15-20%.

· Critical Checks:

o Verify centering roll positioning along the rolling axis.

o Adjust roll opening angles for consistent pressure.

· Benefit: Prevents asymmetric rolling, improving thickness tolerance to ±0.1mm.

· Requirement: The piercing mill’s rolling axis must align with the piercing carriage.

· Consequence of Misalignment:

o "Up-rolling" or "Down-rolling" causes uneven wall distribution.

· Correction: Laser-guided alignment systems ensure ±0.05mm precision.

· Worn Tools Cause:

o Irregular wall thickness (e.g., ±12.5% variation in untreated pipes).

· Maintenance Protocol:

o Replace worn mandrels, guide plates, and rolls every 500-800 production cycles.

· Result: Maintains ±7.5% tolerance (per API 5CT).

· Key Adjustments:

o Equalize top/bottom roll gaps and left/right guide distances.

o Ensure all tools are centered on the rolling axis.

· Outcome: Eliminates lopsided wall thinning.

· Specifications:

o Outer diameter: Φ108mm–Φ114mm

o Wall thickness: ≥25mm (uniform)

· Why It Matters: Thick-walled plugs resist bending, improving piercing stability.

· Material Selection:

o Use thick-walled seamless tubes (or solid billets for smaller sizes).

· Advantage: Reduces bending risk, enhancing wall consistency.

· Tolerances:

o Diameter accuracy: ±0.1mm

o Straightness: ≤5mm deviation

· Fabrication Method:

o Turned & welded (with precision dowels for alignment).

· Impact: Ensures ±0.05mm thickness uniformity in finished pipes.

· Prevent Thinning/Thickening:

o Adjust rolling speeds to avoid mid-process wall reduction.

o Implement real-time ultrasonic thickness monitoring.

· Standard Compliance: Meets ASTM A519 and EN 10305-1 Class E.

By implementing these 9 measures, manufacturers can achieve exceptional steel pipe wall thickness accuracy, drastically reducing scrap rates while guaranteeing compliance with API, ASTM, and EN standards for wall thickness tolerances. For high-precision steel pipes, investing in automated steel pipe wall thickness control systems and rigorous tool maintenance is critical to maintaining consistent quality.

Need precision-engineered seamless steel pipes? Contact Us for pipes with ±5% wall thickness tolerance!