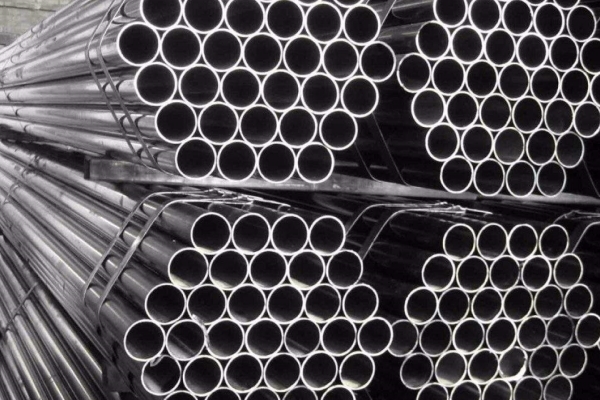

Seamless steel pipes are widely used in oil and gas pipelines due to their high strength and corrosion resistance. However, proper storage is crucial to maintaining their structural integrity and prolonging their service life. Improper storage can lead to surface damage, rust, and contamination, which may compromise the pipe's performance.

In this article, we’ll explore the best practices for storing seamless steel pipes to ensure they remain in optimal condition before installation.

Before storing seamless steel pipes, thorough cleaning is essential to remove oil, grease, dust, and other contaminants. While solvents and emulsions can eliminate organic residues, they cannot remove rust or oxidation. Therefore, additional treatments like acid washing or mechanical cleaning may be necessary.

· Chemical Cleaning (Acid Washing):

o Removes rust, old coatings, and oxidation.

o Ensures a clean surface but may leave shallow anchor patterns.

o Requires proper disposal to avoid environmental pollution.

· Mechanical Cleaning (Wire Brushing):

o Effective for loose rust, scale, and welding slag.

o Manual brushing reaches Sa2 grade, while power tools achieve Sa3.

o Not ideal for tightly bonded oxide layers.

Since seamless steel pipes are prone to rust when exposed to moisture, the following measures should be taken:

· Indoor Storage:

o Store in a dry, well-ventilated warehouse.

o Avoid direct contact with corrosive chemicals.

· Outdoor Storage:

o Elevate pipes on wooden or rubber pads to prevent ground moisture absorption.

o Cover with waterproof tarps to protect from rain and humidity.

· Anti-Corrosion Coatings:

o Apply temporary rust inhibitors or oil-based coatings.

o Regularly inspect for signs of rust formation.

Improper stacking can cause deformation or surface scratches. Follow these guidelines:

· Stacking Arrangement:

o Use wooden or padded separators between layers.

o Avoid excessive height to prevent pipe bending.

· Handling Equipment:

o Use nylon slings or padded clamps to avoid surface damage.

o Never drag pipes on rough surfaces.

· Humidity Control:

o Maintain low humidity levels (below 60%) in storage areas.

o Use dehumidifiers if necessary.

· Temperature Stability:

o Avoid extreme temperature fluctuations to prevent condensation.

Proper storage of seamless steel pipes is critical to maintaining their quality and extending their lifespan. By following these best practices—cleaning, corrosion prevention, careful stacking, and environmental control—you can ensure that your pipes remain in excellent condition for future use.

For industries relying on seamless steel pipes, investing in proper storage solutions will minimize waste, reduce maintenance costs, and enhance operational efficiency.