A seamless steel pipe is manufactured by piercing a solid billet to form a hollow tube, which is then processed through hot rolling, cold rolling, or cold drawing. Unlike welded pipes, seamless steel pipes have no seams, making them stronger and more reliable for high-pressure applications. Their hollow cross-section makes them ideal for fluid transportation, structural components, and mechanical parts.

Compared to solid steel bars, seamless steel pipes offer the same bending and torsional strength while being significantly lighter, making them a cost-effective choice for various industries.

1. Oil & Gas Industry

· Drilling pipes – Withstand extreme underground pressures

· Casing & tubing – Protect wellbores in oil extraction

· Pipelines – Transport crude oil and natural gas efficiently

2. Chemical & Power Plants

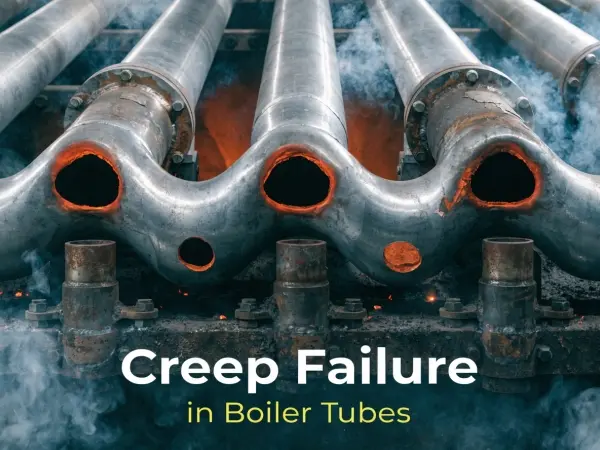

· High-pressure boiler tubes – Handle steam and corrosive fluids

· Heat exchangers – Improve thermal efficiency in power generation

· Chemical transport pipes – Resist acid and alkali corrosion

3. Automotive & Machinery

· Hydraulic cylinders – Ensure smooth operation in heavy machinery

· Bearing sleeves – Reduce friction in rotating parts

· Chassis components – Enhance vehicle structural integrity

4. Construction & Infrastructure

· Scaffolding – Provide lightweight yet strong support

· Bridge & building frameworks – Offer superior load-bearing capacity

5. Aerospace & Defense

· Aircraft hydraulic systems – Maintain performance under extreme conditions

· Missile & rocket components – Ensure precision and reliability

Seamless steel pipes can be categorized based on different factors:

1. By Cross-Section Shape

· Round pipes – Most common for fluid and gas transport

· Special-shaped pipes (Square, Oval, Hexagonal) – Used in structural and mechanical applications

2. By Material Type

· Carbon steel pipes – General-purpose, cost-effective

· Alloy steel pipes – Enhanced strength for high-stress environments

· Stainless steel pipes – Corrosion-resistant for chemical and food industries

· Composite pipes – Multi-layered for specialized uses

3. By Connection Method

· Threaded pipes – Screw-fitted for easy assembly

· Welded pipes – Used when additional reinforcement is needed

4. By Production Process

· Hot-rolled pipes – Made at high temperatures for large diameters

· Cold-drawn pipes – Precision-engineered for tighter tolerances

5. By Application

· Boiler pipes – High-temperature resistance

· Oil well casing pipes – Reinforced for drilling operations

· Structural pipes – Used in construction and machinery

· Hydraulic pipes – Designed for fluid power systems

· Superior Strength – No weak seams, ideal for high-pressure use

· Corrosion Resistance – Long-lasting performance in harsh environments

· Lightweight & Durable – Reduces material costs without sacrificing strength

· Versatility – Suitable for multiple industries, from oil rigs to aerospace

The seamless steel pipe is a vital component in modern industry, offering unmatched reliability for fluid transport, structural support, and mechanical applications. Whether in oil drilling, power plants, or construction, its strength and adaptability make it indispensable.

By understanding its classifications and uses, industries can select the right seamless steel pipe for optimal performance and cost efficiency.