When sourcing high-quality piping for critical applications, choosing a reliable seamless pipe supplier is essential. Seamless steel pipes are widely used in industries requiring superior strength, pressure resistance, and corrosion protection. Whether you need pipes for oil & gas, construction, or mechanical systems, partnering with the right seamless steel pipe supplier ensures durability, performance, and cost-efficiency.

This guide explores key factors in selecting a seamless steel pipe supply partner, common applications, and how to verify quality standards.

Seamless pipes are manufactured through extrusion or rotary piercing, creating a uniform structure without welded seams. This makes them ideal for:

✔ High-pressure systems (hydraulics, boilers, pipelines)

✔ Extreme temperature conditions (refineries, power plants)

✔ Corrosive environments (chemical processing, marine applications)

A trusted seamless steel pipe supplier should offer:

· Multiple material grades (carbon steel, stainless steel, alloy steel)

· Various dimensions (OD from 1/8" to 24"+)

· Custom cutting & coating options (galvanized, epoxy, etc.)

A reputable supplier should provide:

· ASTM/ASME certifications (A106, A53, A333 for low-temp use)

· API 5L compliance (for oil & gas pipelines)

· ISO 9001 certification (quality management)

· Hot-finished vs. cold-drawn seamless pipes (hot-rolled for large sizes, cold-drawn for precision)

· Stock availability (reduces lead time for urgent projects)

· Testing facilities (hydrostatic, ultrasonic, eddy current testing)

· Drilling & extraction (seamless pipes resist high pressure)

· Refinery piping (corrosion-resistant alloys for harsh chemicals)

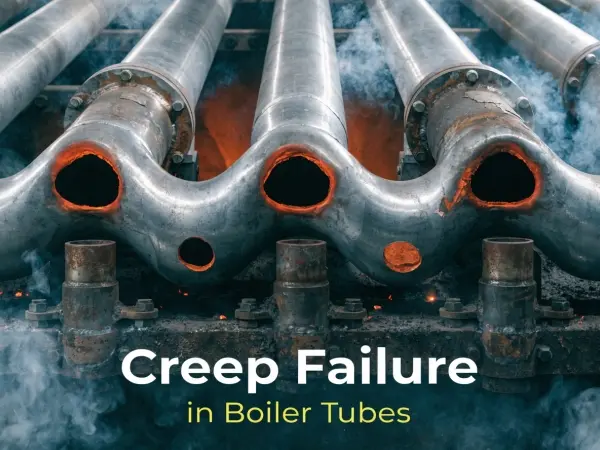

· Boiler tubes (high-temperature resistance)

· Steam pipelines (ASTM A335 P11/P22 grades)

· Structural columns (seamless pipes provide better load-bearing strength)

· Underground piling (thick-walled seamless pipes for stability)

· Hydraulic systems (precision cold-drawn seamless tubes)

· Bearing sleeves & shafts (high-tolerance seamless pipes)

· Chemical composition

· Mechanical properties (tensile strength, yield strength)

· Hydrostatic test results

· No cracks, pits, or scaling

· Smooth internal & external finish

· Industry reputation (Google Reviews, trade references)

· Case studies of past projects

Choosing the right seamless steel pipe supply partner ensures you get durable, high-performance pipes for critical applications. Key takeaways:

✔ Verify certifications (ASTM, API, ISO)

✔ Assess production capabilities (hot/cold-finished, testing)

✔ Compare global vs. local suppliers for cost & lead time

✔ Inspect quality documentation (MTRs, surface checks)

For long-term reliability, work with an established seamless pipe supplier that offers technical support and consistent quality.