A seamless pipe is a long steel tube with a hollow cross-section and no seams along its length. Due to their hollow structure, seamless pipes are widely used for transporting fluids such as oil, natural gas, coal gas, water, and certain solid materials.

The production of seamless pipes mainly involves two methods: the Mannesmann process (cross-rolling method) and the extrusion method.

In this seamless pipe manufacturing process, a billet is first pierced using inclined rolls and then elongated with a rolling mill. This method offers high production efficiency but requires excellent workability of the billet. It is primarily used for manufacturing carbon steel and low-alloy steel pipes.

The extrusion method involves piercing a billet or steel ingot with a piercing machine and then extruding it into a pipe using an extrusion press. Although less efficient than the Mannesmann process, this method is suitable for producing high-strength alloy steel pipes.

Both methods require heating the billet or ingot beforehand, and the resulting pipes are called hot-rolled pipes. Depending on requirements, hot-rolled pipes may undergo further cold processing.

Cold processing improves dimensional accuracy, surface finish, and mechanical properties. The two main cold-processing methods are:

· Cold Drawing: The pipe is pulled through a die to reduce its diameter and increase length.

· Cold Rolling: This method applies the Mannesmann hot-rolling technique to cold-working processes.

1. By Production Method:

o Hot-rolled pipes

o Cold-rolled pipes

o Cold-drawn pipes

o Extruded pipes

2. By Shape:

o Round pipes

o Special-shaped pipes (square, rectangular, oval, hexagonal, triangular, etc.)

3. By Material:

o Carbon steel pipes

o Low-alloy steel pipes

o High-quality carbon steel pipes

o Alloy steel pipes

o Stainless steel pipes

4. By Application:

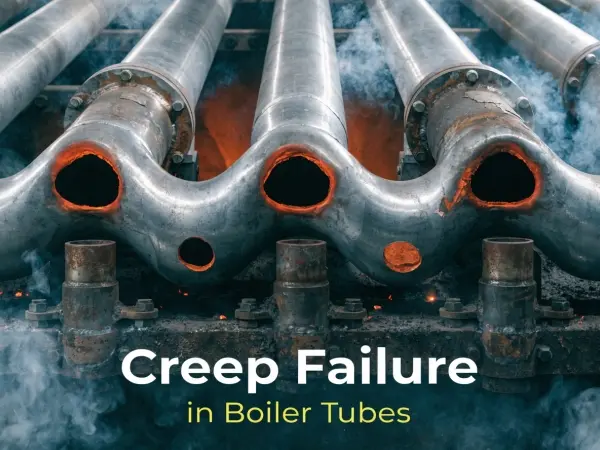

o Boiler pipes

o Geological pipes

o Oil pipes

Understanding the seamless pipe manufacturing process helps in selecting the right type of pipe for industrial applications. Whether through hot rolling or cold processing, seamless pipes offer superior strength and durability for critical fluid transportation systems.

For high-quality seamless pipes, choosing the right manufacturing method ensures optimal performance in demanding environments.