In industries such as oil and gas, petrochemicals, and power generation, large diameter seamless steel pipes are critical for transporting fluids under extreme conditions. These pipes must withstand high temperatures, pressure fluctuations, and corrosive environments without compromising structural integrity. This article explores how large diameter seamless steel pipes are engineered to handle such challenges, ensuring durability and long-term performance.

Many industrial applications expose pipelines to extreme heat, which can cause thermal expansion, material degradation, and weakening of the pipe structure. Large diameter seamless steel pipes are manufactured using high-grade alloys, such as ASTM A335 P11/P22 or stainless steel, which maintain strength even at elevated temperatures.

Key features that enhance heat resistance:

· Thermal stability: Advanced metallurgical compositions prevent deformation.

· Oxidation resistance: Special coatings or chromium-rich alloys reduce scaling.

· Low thermal expansion: Minimizes stress under temperature fluctuations.

Corrosion is a major concern in pipelines transporting water, chemicals, or hydrocarbons. Large diameter seamless steel pipes combat corrosion through:

· Material selection: Stainless steel (316L, 904L) or corrosion-resistant alloys (Inconel, Duplex).

· Protective coatings: Epoxy, polyethylene, or zinc coatings shield against chemical attacks.

· Cathodic protection: Electrochemical methods prevent rust in buried or submerged pipes.

Unlike welded pipes, large diameter seamless steel pipes have no weak seams, making them ideal for high-pressure and high-temperature applications. Benefits include:

· Uniform strength: No weld joints mean fewer failure points.

· Superior pressure handling: Ideal for deep-sea pipelines and high-pressure steam systems.

· Longer lifespan: Reduced risk of leaks and cracks under stress.

· Oil & Gas: Transporting crude oil and natural gas in subzero Arctic or high-temperature desert environments.

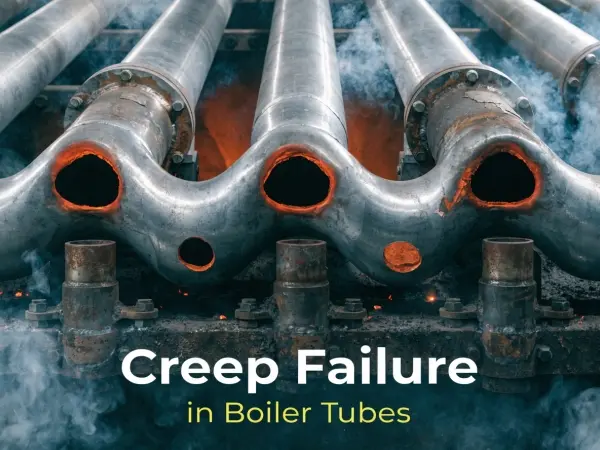

· Power Plants: Carrying superheated steam in boilers and turbines.

· Chemical Processing: Handling aggressive acids and solvents without degradation.

Large diameter seamless steel pipes are engineered to excel in extreme temperatures and corrosive settings, ensuring reliability in critical industries. By leveraging advanced materials, protective treatments, and seamless construction, these pipes deliver unmatched performance and longevity.

For industries requiring robust piping solutions, investing in high-quality large diameter seamless steel pipes is essential for safety, efficiency, and cost-effectiveness.