Sourcing reliable pipes for critical projects is stressful. Failures cost millions and ruin reputations. You need materials that withstand extreme conditions without hesitation. A high pressure seamless pipe is a specialized steel tube manufactured without welding seams, designed to withstand extreme internal pressure and temperatures. Unlike welded pipes, it offers superior uniform strength, making it essential for boilers, hydraulic systems, and oil refineries where safety is non-negotiable.

I have seen many project managers struggle with pipe specifications. They often confuse general piping with specialized high-pressure requirements. This mistake can lead to safety hazards. I want to help you understand the details clearly so you can make the best choice.

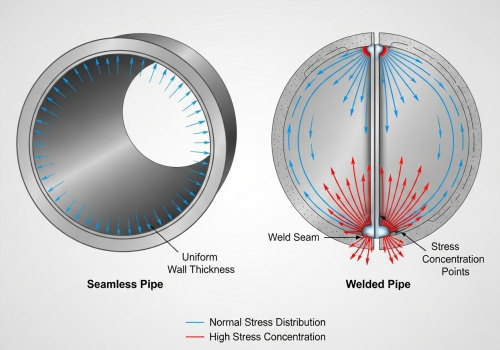

Welded pipes often fail at the seam under stress. This risk creates anxiety for safety engineers. You want a solution that guarantees structural integrity. The primary advantage is the lack of a weld seam, which eliminates the weakest point of a standard pipe. These pipes offer high tensile strength, exceptional temperature resistance, and a smooth surface that improves fluid flow and reduces corrosion risks in heavy industrial applications.

When we talk about a high pressure seamless pipe, we are talking about a product made from a solid round steel billet. The manufacturer heats this billet and pushes or pulls it over a form until the steel is shaped into a hollow tube. This process is very different from welded pipes, where a flat sheet is rolled and fused together. Because there is no seam, the pressure handling capacity is much higher. In my experience at Centerway Steel, I have seen that the burst pressure of a seamless pipe is roughly 20% higher than a welded pipe of the same size. This is crucial for your high-stakes projects. Also, the material consistency is better. When you weld a pipe, the heat changes the steel structure near the weld zone. This can create a weak spot. A seamless pipe has a uniform structure throughout. This means it resists corrosion better and handles thermal expansion evenly. Here is a simple breakdown of why you should choose seamless over welded for high-pressure needs:

| Feature | High Pressure Seamless Pipe | Welded Pipe |

|---|---|---|

| Pressure Rating | Very High (Uniform strength) | Moderate (Weld is a weak point) |

| Defects | Low risk (No seam) | Higher risk (Porosity in weld) |

| Corrosion | Uniform resistance | Weld zone is prone to corrosion |

| Cost | Higher initial cost | Lower initial cost |

| Safety | Best for critical applications | Suitable for low/medium pressure |

Using the wrong pipe grade in a power plant or refinery is a recipe for disaster. You need to know exactly where these high-grade materials belong. These pipes are critical in sectors requiring zero leakage tolerance. They are the standard for high-pressure boiler tubes, petroleum cracking, chemical fertilizer equipment, and hydraulic cylinders. If your project involves transporting steam, oil, or gas under extreme pressure, this is your only safe option.

I have worked with many clients in the construction and energy sectors. They often ask where exactly they must use these specific pipes. The applications are vast, but they all share one common trait: extreme conditions. First, let's look at the Petroleum Industry. Here, pipes transport crude oil and natural gas. The pressure underground is immense. A high pressure seamless pipe is used for casing, tubing, and drilling pipes. It must resist not just pressure, but also the corrosive nature of sulfur in the oil. Second, consider the Power Generation Industry. In thermal power plants, boilers produce superheated steam. This steam travels through pipes at very high speeds and temperatures. If a pipe bursts here, it can shut down the whole plant. We supply pipes that meet ASTM A335 or DIN 17175 standards specifically for these high-temperature jobs. Third, look at Mechanical Engineering. Large construction vehicles like excavators use hydraulic systems. These systems rely on fluid under pressure to move heavy arms. The cylinders in these machines are almost always made from seamless tubing to prevent bursting during a lift. Here is how different industries utilize these pipes based on my observation:

| Industry | Specific Application | Key Requirement |

|---|---|---|

| Oil & Gas | Flow lines, Downhole tubing | Tensile strength & Corrosion resistance |

| Chemical | Cracking tubes, Heat exchangers | Chemical stability at high heat |

| Power | Boiler tubes, Steam lines | Creep rupture strength |

| Automotive | Hydraulic cylinders, Airbags | Precision & Burst resistance |

Understanding these applications helps you plan your procurement list more accurately. You do not want to over-specify for a water line, but you definitely cannot under-specify for a steam line.

Finding a "one-stop" supplier who delivers on time is difficult. Delays and quality issues hurt your bottom line. You need a partner, not just a seller. To ensure reliability, look for suppliers with full certifications like ISO 9001 and API. Verify their testing capabilities, including hydrostatic and ultrasonic testing. A good supplier integrates production with inventory management to handle large diameter or heavy wall thickness requirements efficiently.

I know that for a Purchasing Manager, the biggest headache is quality assurance. You are in Germany; you expect precision. When you buy from overseas, you need to trust that the product matches the paperwork. At Centerway Steel, we have been doing this since 1996. I have learned that a piece of paper is not enough. You must look for a supplier who performs rigorous testing before the goods leave the factory. For a high pressure seamless pipe, the most important test is the Hydrostatic Test. The manufacturer fills the pipe with water and pressurizes it higher than its operating limit. If it holds, it is safe. You should also ask for Non-Destructive Testing (NDT). This includes Ultrasonic testing or Eddy Current testing. These methods use sound waves or electricity to find hidden cracks inside the steel wall that the eye cannot see. Another factor is the supply chain integration. A good supplier does not just make pipes; they manage inventory. Sometimes you need a pipe with a very thick wall or a large diameter that is not standard. An integrated supplier can adjust production or source from stock immediately. Here is a checklist I recommend you use when evaluating a supplier:

1. Certifications: Do they hold ISO 9001, API 5L, and CE marks?

2. Third-Party Inspection: Are they willing to let SGS, TUV, or BV inspect the goods? We welcome this at Centerway because it builds trust.

3. Surface Finish: Is the pipe pickled or shot-blasted? A smooth surface prevents rust and makes inspection easier.

4. Traceability: Can they trace every pipe back to the heat number of the raw steel billet? If a supplier can answer "yes" to these questions, you can trust them with your project. It saves you time and protects your company from costly replacements later.

High pressure seamless pipe is essential for safety in extreme industrial environments. By understanding its seamless structure, specific applications, and quality requirements, you ensure project success and operational security.