Hot rolled seamless steel tubes are critical components in industries such as oil and gas, chemical processing, power generation, and construction. Their superior strength, uniformity, and durability make them indispensable in high-pressure and high-temperature applications. Ensuring the quality of these tubes is therefore essential. This article provides an in-depth look at quality standards, testing methods, and technical considerations, helping engineers, quality control professionals, and procurement specialists make informed decisions.

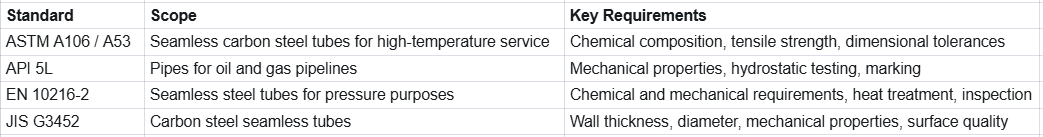

Hot rolled seamless steel tubes must meet strict standards to ensure reliable performance. Key international standards include:

Compliance with these standards ensures that tubes meet customer specifications, withstand operational stresses, and adhere to safety regulations.

Reliable performance of hot rolled seamless steel tubes requires comprehensive testing, both during and after production.

A robust quality assurance program integrates testing with process monitoring:

1. Raw Material Verification: Confirm chemical composition and supplier certifications.

2. Process Control: Monitor rolling temperature, reduction ratios, and cooling rates.

3. Sampling and Documentation: Use statistical sampling methods and maintain traceable test certificates.

This systematic approach ensures that each hot rolled seamless steel tube meets strict mechanical and chemical requirements, reducing the risk of failure in demanding applications.

Ensuring the quality of hot rolled seamless steel tubes through international standards and rigorous testing is essential for high-pressure, high-temperature, and safety-critical applications. From chemical composition analysis and mechanical testing to non-destructive inspection and dimensional verification, each step contributes to reliable performance and operational safety.

For industries seeking high-quality tubing solutions, selecting the right seamless steel tube is crucial. Our hot rolled seamless steel tubes are manufactured to meet ASTM, API, and EN standards, with thorough testing to guarantee mechanical strength, corrosion resistance, and dimensional accuracy. Choosing certified seamless steel tubes ensures both performance and safety across applications such as oil and gas pipelines, chemical plants, and industrial pressure systems.