In industrial applications where extreme heat and pressure are common, seamless carbon steel pipe for high temperature service is the preferred choice. These pipes offer unmatched durability, strength, and resistance to thermal stress, making them essential in power plants, oil refineries, petrochemical facilities, and boiler systems.

This comprehensive guide explores the features, benefits, manufacturing process, applications, and industry standards for carbon steel seamless pipes designed for high-temperature environments.

A seamless carbon steel pipe is produced by extruding a solid billet through a piercing rod to form a hollow tube without any welded seams. This manufacturing method ensures:

· Uniform strength – No weak points from welding

· Higher pressure resistance – Ideal for critical applications

· Better corrosion resistance – Reduced risk of leaks and cracks

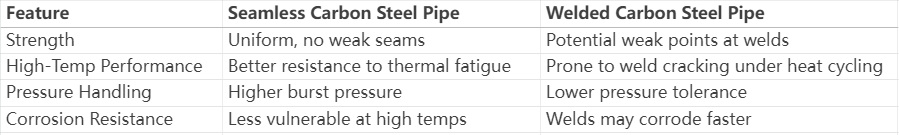

Compared to welded pipes, seamless carbon steel pipe for high temperature service performs exceptionally well under thermal cycling and mechanical stress.

· Withstands temperatures up to 750°F (400°C) and beyond (depending on grade)

· Retains structural integrity under continuous thermal exposure

· Resists deformation under extreme pressure

· Suitable for steam lines, superheaters, and heat exchangers

· Carbon steel naturally resists scaling at high temperatures

· Optional coatings (e.g., galvanization, chroming) enhance longevity

· More affordable than stainless steel or alloy pipes

· Lower maintenance costs due to long service life

The production of carbon steel seamless pipes involves several key steps:

1. Billet Heating – A solid steel billet is heated to high temperatures.

2. Piercing & Rolling – A mandrel pierces the billet, forming a hollow shell.

3. Elongation & Sizing – The pipe is stretched and rolled to precise dimensions.

4. Heat Treatment – Enhances mechanical properties (annealing, quenching).

5. Finishing & Inspection – Surface treatment, testing (ultrasonic, hydrostatic).

This process ensures a seamless carbon steel pipe for high temperature service with superior reliability.

· Boiler tubes & superheaters – Handle high-pressure steam

· Steam pipelines – Transport overheated steam efficiently

· Refinery piping – Transports hot crude oil and gases

· Downhole tubing – Resists extreme geothermal heat

· Heat exchangers & reactors – Withstand corrosive, high-temperature fluids

· Furnace & burner systems – Maintain performance under thermal stress

· Exhaust systems – Endures extreme heat from engines

· Hydraulic systems – Handles high-pressure, high-temperature fluids

To ensure safety and performance, carbon steel seamless pipes must comply with international standards, including:

· ASTM A106 – Covers seamless pipes for high-temperature service

· API 5L – Specifies requirements for pipeline transportation

· ASME SA53 – Standard for general-purpose seamless pipes

· EN 10216 – European standard for pressure-resistant pipes

Manufacturers must conduct hydrostatic tests, ultrasonic inspections, and hardness tests to verify quality.

For critical applications, seamless carbon steel pipe for high temperature service is the superior choice.

To maximize the lifespan of carbon steel seamless pipes in high-heat environments:

✔ Regular inspections for scaling, corrosion, or deformation

✔ Proper insulation to minimize thermal stress

✔ Use compatible fittings & supports to prevent stress fractures

✔ Follow industry standards for pressure and temperature limits

When reliability under extreme heat is non-negotiable, seamless carbon steel pipe for high temperature service delivers unmatched performance. Its seamless construction, high strength, and cost-efficiency make it indispensable in power plants, refineries, and industrial heating systems.

Looking for high-quality seamless carbon steel pipes for high-temperature applications?

✅ Premium-grade materials meeting ASTM/API standards

✅ Custom sizes & specifications available

✅ Competitive pricing & fast delivery

Contact our experts today for technical specifications and quotes! We'll help you find the perfect seamless carbon steel pipe for high temperature service solution for your project.