When it comes to industrial piping systems, durability, efficiency, and reliability are critical. Among the best solutions available today is the SS seamless pipe (stainless steel seamless pipe), which offers unmatched performance in demanding environments. Whether in oil and gas, chemical processing, or power generation, SS seamless pipes provide superior strength, corrosion resistance, and longevity.

In this article, we explore the key advantages of using SS seamless pipes in industrial applications and why they are the preferred choice for engineers and project managers.

Unlike welded pipes, SS seamless pipes are manufactured without seams, eliminating weak points that can lead to leaks or ruptures under high pressure. This makes them ideal for industries requiring robust piping solutions, such as:

· Oil and gas pipelines

· High-pressure steam systems

· Hydraulic systems

Their uniform structure ensures consistent performance, even in extreme temperatures and harsh conditions.

Stainless steel is renowned for its ability to resist corrosion, making SS seamless pipes perfect for industries dealing with corrosive fluids, acids, and saltwater environments. Applications include:

· Chemical processing plants

· Marine and offshore installations

· Water treatment facilities

The absence of weld seams further enhances corrosion resistance, reducing maintenance costs and downtime.

Seamless pipes have a smooth internal surface, minimizing friction and pressure drops. This feature is crucial for industries requiring efficient fluid transport, such as:

· Food and beverage processing

· Pharmaceutical manufacturing

· Petrochemical refineries

The improved flow efficiency reduces energy consumption and enhances operational productivity.

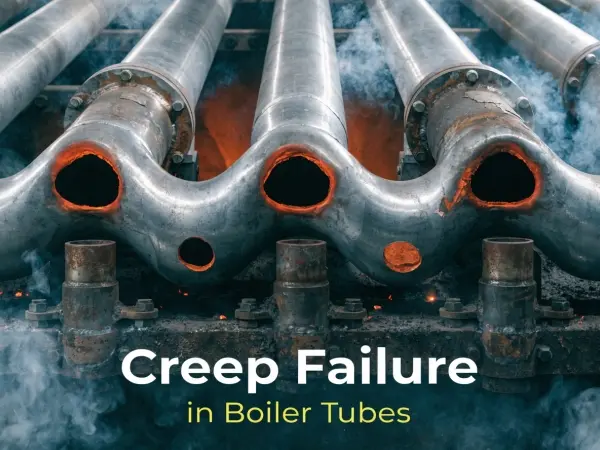

Industries like power generation and aerospace demand materials that can withstand extreme conditions. SS seamless pipes excel in high-temperature and high-pressure applications, ensuring safety and reliability in:

· Boiler systems

· Heat exchangers

· Nuclear power plants

Their ability to maintain structural integrity under stress makes them indispensable in critical operations.

While the initial cost of SS seamless pipes may be higher than welded alternatives, their longevity and low maintenance requirements result in significant cost savings over time. Reduced risk of leaks, cracks, and failures translates to fewer replacements and repairs.

From unmatched durability to superior corrosion resistance, SS seamless pipes are a smart investment for industrial applications. Their seamless construction ensures reliability, efficiency, and long-term performance, making them the top choice for engineers worldwide.

If you're looking for a high-performance piping solution, consider SS seamless pipes to enhance your industrial operations while minimizing downtime and maintenance costs.

Upgrade your infrastructure today with the reliability of SS seamless pipes!