Seamless pipes are essential components in industries such as oil and gas, petrochemical, power generation, and automotive due to their high strength, leak-proof structure, and ability to withstand extreme pressures. Unlike welded pipes, seamless pipes are manufactured without any seams, making them ideal for critical applications.

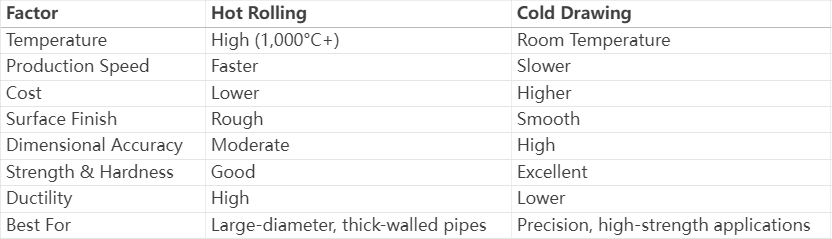

Two primary manufacturing methods are used to produce seamless pipes: hot rolling and cold drawing. Each process has distinct advantages and limitations, influencing the pipe's mechanical properties, surface finish, and cost. This article compares both methods to help you determine the best option for your needs.

Hot rolling involves heating a solid steel billet to extremely high temperatures (typically above 1,000°C) until it becomes malleable. The heated billet is then pierced and rolled to form a hollow tube, which is further elongated and sized to the desired dimensions.

✔ Cost-Effective for Large Production – Hot rolling is faster and more economical for mass production, especially for larger diameters.

✔ Better Ductility & Toughness – The high-temperature process enhances the material’s ability to deform without cracking.

✔ Uniform Wall Thickness – Suitable for pipes requiring consistent structural integrity.

✔ Ideal for Thick-Walled Pipes – Hot rolling can produce pipes with thicker walls more efficiently than cold drawing.

✖ Rougher Surface Finish – Requires additional machining or polishing for smoothness.

✖ Less Dimensional Precision – Tolerances are looser compared to cold-drawn pipes.

✖ Potential for Scaling – High temperatures can lead to oxide formation, requiring post-treatment.

· Oil & gas pipelines

· Structural and construction applications

· Boiler tubes and heat exchangers

Cold drawing involves pulling a hot-rolled seamless pipe through a die at room temperature to reduce its diameter and wall thickness. This process enhances mechanical properties and improves surface quality.

✔ Superior Surface Finish – Smoother and more precise than hot-rolled pipes.

✔ Tighter Dimensional Tolerances – Ideal for high-precision applications.

✔ Increased Strength & Hardness – Cold working enhances tensile strength and durability.

✔ Better Machinability – Reduced need for additional finishing processes.

✖ Higher Production Cost – More time-consuming and labor-intensive.

✖ Limited to Smaller Diameters – Not as efficient for large pipes.

✖ Reduced Ductility – The cold-working process can make the material more brittle.

· Hydraulic systems

· Precision machinery and automotive components

· Medical and aerospace industries

The choice between hot rolling and cold drawing depends on your specific requirements:

✅ Choose Hot-Rolled Seamless Pipes If:

· You need cost-effective production for large-diameter pipes.

· High ductility and toughness are critical.

· Surface finish is not a primary concern.

✅ Choose Cold-Drawn Seamless Pipes If:

· You require high precision and a smooth surface.

· Superior strength and hardness are needed.

· The application demands tight tolerances (e.g., hydraulic systems).

Both hot rolling and cold drawing play crucial roles in manufacturing seamless pipes, each offering unique benefits. Hot rolling is ideal for large-scale, economical production, while cold drawing excels in precision and high-performance applications.

When selecting seamless pipes, consider factors such as cost, mechanical properties, and end-use requirements to determine the best manufacturing process for your project.

By understanding these differences, you can ensure optimal performance, durability, and cost-efficiency for your industrial applications.