Selecting the perfect seamless steel tube for your project can be challenging due to the variety of options available. Whether for industrial, construction, or mechanical applications, understanding key factors like size, material grade, and compliance standards is essential. This in-depth guide will help you make an informed decision while optimizing performance and cost-efficiency.

The dimensions of a seamless steel tube directly impact its functionality. Below is a detailed breakdown of critical sizing considerations:

· Standard sizes: Ranging from 1/8" to 24" or larger.

· Precision requirements: Tighter tolerances for high-pressure applications.

· Compatibility: Must match connectors, flanges, and machinery.

Pro Tip: Always check engineering drawings before ordering to avoid mismatches.

· Schedule numbers (SCH 40, 80, 160): Define wall thickness in standardized piping.

· Thin-wall vs. thick-wall tubes:

o Thin-wall: Lightweight, cost-effective, ideal for low-pressure uses.

o Thick-wall: High-pressure resistance, used in oil & gas, hydraulics.

Example: A seamless steel tube with SCH 80 is thicker than SCH 40, offering better durability.

· Standard lengths: 6m, 12m (20ft, 40ft).

· Custom-cut lengths: Minimizes waste in specialized projects.

Industry Insight: Longer tubes reduce welding joints, enhancing structural integrity.

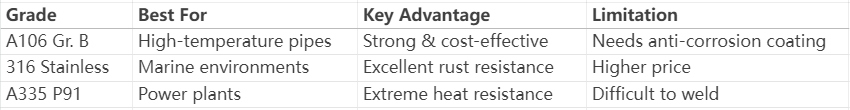

Not all seamless steel tubes are the same—material grade determines performance. Here’s a comparison of the most common types:

· Grades: ASTM A106 (high-temp), A53 (general use).

· Applications: Boilers, structural supports, machinery.

· Pros: Affordable, strong, weldable.

· Cons: Prone to corrosion without coating.

· Grades: 304 (general use), 316 (marine/chemical resistance), 321 (high-temp).

· Applications: Food processing, chemical plants, medical equipment.

· Pros: Rust-proof, hygienic, long lifespan.

· Cons: Higher cost than carbon steel.

· Grades: ASTM A335 (P11, P22, P91 for high heat).

· Applications: Power plants, refineries, aerospace.

· Pros: Heat & pressure resistant, durable.

· Cons: Expensive, requires expertise in welding.

Comparison Table:

Using uncertified seamless steel tubes can lead to failures. Below are the most critical standards:

· ASTM A53: General structural & mechanical tubing.

· ASTM A106: High-temperature service.

· ASTM A312: Stainless steel pipes for corrosive environments.

· API 5L: Mandatory for oil & gas pipelines.

· Grades: X42, X52, X80 (higher numbers = stronger steel).

· EN 10216: Covers pressure-resistant tubes.

· ISO 9001: Quality management certification for manufacturers.

Why It Matters: Certified seamless steel tubes undergo strict testing (hydrostatic, ultrasonic) to ensure reliability.

To ensure you select the best seamless steel tube, ask these questions:

✔ Size: Does the OD, wall thickness, and length match project specs?

✔ Grade: Is the material suitable for temperature, pressure, and corrosion needs?

✔ Standards: Does it comply with ASTM, API, or EN requirements?

✔ Supplier Reputation: Are they certified with proper testing reports?

Selecting the right seamless steel tube requires careful consideration of size, material grade, and industry standards. By following this guide, you can ensure optimal performance, safety, and cost-efficiency for your project.

Looking for high-quality seamless steel tubes? Contact us today for expert advice and premium products tailored to your needs!