In the oil and gas, petrochemical, and power generation industries, pipelines must endure extreme operating conditions. Seamless line pipe has emerged as the preferred choice for high pressure pipe and high temperature pipe systems due to its unmatched strength, durability, and reliability. Unlike welded pipes, seamless variants eliminate weak points, ensuring superior performance in the most demanding environments.

This article explores the key advantages of seamless line pipe, its material properties, applications, and why it outperforms alternatives in high pressure and high temperature scenarios.

Seamless line pipe is manufactured through a process that involves extruding a solid billet into a hollow tube without any welding seams. This method ensures:

· Uniform strength throughout the pipe

· No weak points that could lead to failure under stress

· Superior resistance to cracking and corrosion

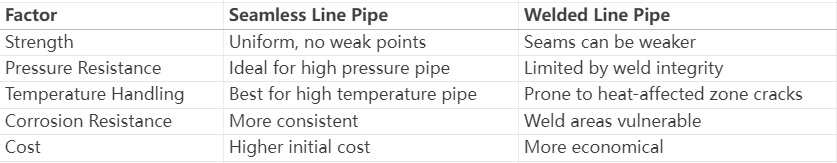

By contrast, welded pipes have seams that can become vulnerable under high pressure pipe or high temperature pipe conditions, making seamless pipes the safer choice.

Industries that depend on seamless line pipe include:

· Oil & Gas: Offshore drilling, deep-water extraction, and high-pressure transmission

· Power Generation: Steam lines, boiler tubes, and thermal power plants

· Petrochemical: Refineries and chemical processing under extreme heat

· Nuclear Energy: Coolant systems requiring leak-proof integrity

In high pressure pipe systems, such as hydraulic fracturing (fracking) and subsea pipelines, seamless line pipe offers:

· Higher burst strength compared to welded pipes

· Reduced risk of leaks due to the absence of weld seams

· Better fatigue resistance under cyclic pressure changes

Common materials used in seamless line pipe for high pressure applications include:

· Carbon Steel (API 5L Grade B/X52/X65): Cost-effective and strong

· Alloy Steel (P11, P22, P91): Enhanced strength for extreme conditions

· Stainless Steel (304, 316, 321): Corrosion resistance in aggressive environments

Seamless line pipe excels in high temperature pipe applications, such as steam distribution and exhaust systems, because:

· Lower thermal expansion reduces stress on joints

· Creep resistance prevents deformation under prolonged heat exposure

· Oxidation resistance extends service life in extreme heat

· Power Plant Steam Lines: Operating at 500°C+

· Refinery Piping: Handling hot crude oil and gases

· Geothermal Energy: Transporting superheated fluids

While welded pipes may be cheaper, seamless line pipe provides long-term savings through reduced maintenance and downtime.

· Precision cold drawing for tighter tolerances

· Enhanced heat treatment for improved toughness

· Non-destructive testing (NDT) for defect detection

As industries shift toward cleaner energy, seamless line pipe will play a key role in:

· Hydrogen transport (requiring high-pressure resistance)

· Carbon capture and storage (CCS) pipelines

· Geothermal and nuclear energy systems

For industries operating under high pressure pipe and high temperature pipe conditions, seamless line pipe delivers unmatched performance. Its superior strength, leak resistance, and durability make it the safest and most reliable option for critical applications.

As technology advances, seamless line pipe will continue to evolve, meeting the demands of modern energy infrastructure. Investing in high-quality seamless pipes ensures long-term operational efficiency and safety.

Upgrade your pipeline systems with seamless line pipe today for maximum reliability in extreme conditions!