You face tight project deadlines and demand exact tolerances. Inferior materials cause equipment failure and costly downtime. You need piping solutions that guarantee accuracy and durability under high pressure. Cold drawn seamless steel pipes for precision engineering provide superior dimensional accuracy and exceptional surface finishes. By pulling the metal through a die at room temperature, we increase the steel's tensile strength and hardness, making these tubes the ideal choice for hydraulic systems and critical mechanical parts.

Many project managers overlook the specific benefits of the cold drawing process until they face installation issues. I want to walk you through exactly how these pipes are made and why they are the standard for high-performance applications.

Raw steel often lacks the specific shape and strength your designs require. Machining rough pipes down to size wastes material and slows your production line significantly. The cold drawing process pulls the tube through a precise die at room temperature. This refines the grain structure, ensuring uniform wall thickness and precise outer diameters without the need for excessive machining later.

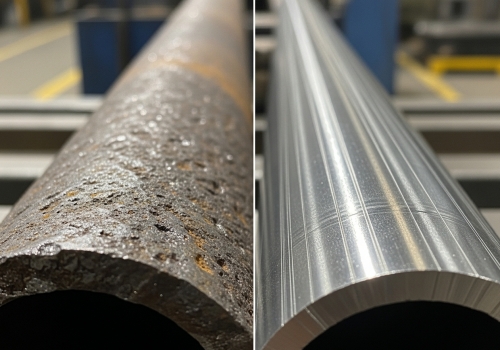

I have seen many clients struggle with the inconsistencies of hot-rolled steel. The cold drawing process solves this. We start by selecting high-quality carbon or alloy structural steel. This is the foundation. Before we even begin shaping, we pickle the pipe blanks. This acid wash removes rust and scale. It leaves the surface clean. Then, we coat the pipe with a lubricant. This is crucial. It allows the steel to pass through the die smoothly. We do not heat the steel during the drawing phase. We pull it through a die that is smaller than the current diameter of the pipe. This stretches the steel. It compresses the walls. Because this happens at room temperature, the steel crystals elongate. This changes the mechanical properties. The pipe becomes stronger and harder. The result is a tube with a smooth surface. It feels polished to the touch. The dimensions are exact. You do not need to worry about large variances in wall thickness. This process aligns the grain structure of the metal. It makes the pipe resistant to internal pressure. For my customers requiring cold drawn seamless steel pipes for precision engineering, this process is the only way to guarantee the product fits their specific machinery without extra work.

Using standard pipes in high-stress machinery often leads to leaks and structural failures. You cannot afford the safety risks or the financial burden of replacing parts frequently. These pipes provide tighter size tolerances and better surface quality than hot-rolled alternatives. This means less machining time for your team and significantly higher mechanical strength for your critical equipment.

When I discuss project requirements with engineers, they often ask about the real difference between hot rolled and cold drawn options. The answer lies in precision and performance. Cold drawn seamless steel pipes for precision engineering are not just about looks. The smooth surface reduces friction in hydraulic applications. This extends the life of your seals and moving parts. The increased yield strength is another major benefit. Because the metal undergoes work hardening, it can handle higher pressures. You can often use a pipe with a thinner wall to hold the same pressure as a thicker hot-rolled pipe. This saves weight in automotive or aerospace designs. To help you understand the specific advantages, I have created a comparison table below. This highlights why cold drawn is the superior choice for precision work.

| Feature | Hot Rolled Seamless Pipe | Cold Drawn Seamless Pipe |

|---|---|---|

| Dimensional Tolerance | Looser, wider variations | Very tight, high precision |

| Surface Finish | Rough, covered in scale | Smooth, shiny, scale-free |

| Mechanical Strength | Lower yield strength | Higher yield strength due to work hardening |

| Machinability | Requires more machining | Excellent, requires less machining |

| Cost | Lower initial cost | Higher value due to reduced processing time |

Steel that is too hard will crack under vibration. Steel that is too soft will bend under heavy loads. You need the perfect balance to ensure longevity. We use specific heat treatments like annealing and normalizing to adjust the steel's internal structure. This relieves internal stress caused by the drawing process and ensures the pipe meets your exact mechanical requirements.

After we cold draw the pipes, the steel is very hard. It contains internal stresses. If we ship it like this, it might be too brittle for some uses. This is where heat treatment becomes vital. I always advise my clients to specify the delivery condition they need. We apply heat to change the microstructure of the metal. For example, we use annealing. We heat the metal and let it cool slowly. This softens the steel. It makes it easier for you to bend or cut the pipe later. Another method is normalizing. We heat the steel and cool it in still air. This refines the grain size. It gives the steel a uniform structure. It improves toughness. If you need high wear resistance, we use quenching and tempering. We cool the hot steel rapidly in oil or water. This makes it very hard. Then we heat it again to a lower temperature. This brings back some toughness so it does not shatter. Understanding these treatments ensures you get the right performance.

| Treatment Type | Process Description | Main Purpose |

|---|---|---|

| Annealing | Heat and cool slowly | Softens steel, improves ductility |

| Normalizing | Heat and cool in air | Refines grain, improves machinability |

| Quenching | Heat and cool rapidly | Increases hardness and strength |

| Tempering | Heat below critical temp after quenching | Reduces brittleness, maintains hardness |

Finding the right material for specific industries is confusing and risky. One wrong material choice compromises the safety of your entire operation and endangers your reputation. From hydraulic cylinders to automotive airbags, these tubes serve industries requiring absolute safety and precision. They are the backbone of heavy machinery, sensitive instrumentation, and high-pressure fluid transport systems.

I have supplied cold drawn seamless steel pipes for precision engineering to partners in over 100 countries. The versatility of this product always impresses me. In the automotive industry, manufacturers use our tubes for shock absorbers and steering columns. They need the high strength-to-weight ratio to keep cars safe but light. In the heavy machinery sector, these pipes are essential. Think about the hydraulic cylinders on a massive excavator. They must withstand immense pressure all day long. A small defect in the pipe wall would cause a catastrophic burst. Our cold drawn pipes handle this stress easily. We also see huge demand in the energy sector. Oil and gas refineries use these pipes for heat exchangers. The smooth internal surface helps fluid flow efficiently. It prevents clogging and corrosion buildup. Whether you are building aircraft engines or simple transmission shafts, the consistency of cold drawn seamless tubing provides the reliability you need.

Cold drawn seamless pipes offer unmatched precision, strength, and surface quality. By selecting the right processing and heat treatment, we ensure your projects succeed with safety and efficiency.