Boiler system failures can ruin your project timeline and destroy your budget instantly. You must select the correct piping materials to ensure safety and avoid costly operational downtime. A high pressure boiler tube is a specialized seamless steel pipe designed to withstand extreme heat and internal pressure. Essential for superheaters and water-cooled walls, these tubes resist oxidation and corrosion, ensuring the long-term safety and efficiency of power plants and petrochemical facilities.

I have worked in this industry for many years. I have seen many buyers make mistakes because they did not understand the product deeply. I want to share my knowledge with you. This will help you stop reading other guides and start making the right choices.

When we talk about a high pressure boiler tube, we are talking about safety first. These tubes work in very harsh places. They face high heat and high pressure every day. They also face hot smoke and water vapor. If the material is weak, the tube will break. First, the material must have high durability. This means it must not change shape or break over a long time. In our factory, we test this strictly. We want to make sure the pipeline runs well for years. Second, the tube must resist oxidation. In high heat, metal can rust quickly. The tube wall can get thin. If it gets too thin, it will burst. Third, the structure of the steel must be stable. High heat can change the inside of the steel. This leads to cracks. We usually use three types of steel. We use high-quality carbon structural steel. We use alloy structural steel. We also use stainless heat-resistant steel.

· Alloy Steel: We add elements to make it stronger. It handles higher heat.

· Stainless Steel: Best for fighting corrosion. Here is a simple table to help you understand the grades we often supply at Centerway Steel:

| Steel Category | Common Grades | Key Characteristic | Typical Application |

|---|---|---|---|

| Carbon Steel | 20G, 20MnG | High toughness, good plasticity | Water-cooled walls, general pipes |

| Alloy Steel | 15CrMoG, 12Cr1MoVG | High heat resistance, high strength | Superheaters, Reheaters |

| Stainless Steel | TP304, TP316 | Excellent corrosion resistance | High-corrosion environments |

The way we make the tube is just as important as the material. The process for a high pressure boiler tube is very strict. It is similar to making standard seamless tubes, but the controls are tighter. We mainly use hot rolling and cold drawing. In hot rolling, we heat the steel billet until it is soft. Then, we roll it many times to make the shape. This is good for bigger sizes. Cold drawing is different. We pull the tube when it is cool. This makes the size very precise. It also makes the surface very smooth. Sometimes, we use a hot expansion process. This helps us make tubes with larger diameters if you need them. But making the shape is not enough. We must control the quality of the raw steel billet. We check the chemicals inside it. We check the surface. We do not skip any steps. After we make the tube, we test it again. We do a water pressure test. This checks for leaks. We do a flattening test. This checks for cracks. At Centerway Steel, we know that EPC companies care about reliability. We follow ISO 9001 and ISO 14001 standards. We ensure every tube can handle the job. This process removes the risk for you. You do not want a tube that fails during a pressure test on site. That causes big delays.

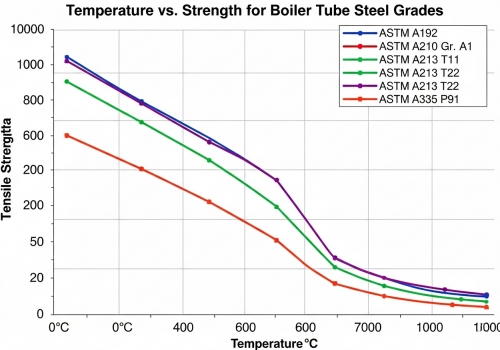

You cannot just buy any tube. You must follow the rules. There are many standards in the world. In China, we use GB standards. In the USA, they use ASME. in Germany and Europe, they use DIN. You need to know which one your project needs. For example, GB3087 and GB5310 are very common in China. But for my global clients, I often supply tubes meeting ASME SA210 or ASME SA213. These are the rules for boilers and pressure vessels. If your project is in Europe, you might ask for DIN 17175. We can provide all of these. We have certificates from SGS, BV, and TUV to prove it. Let's look deeper at performance. The tube needs high tensile strength. This means it is hard to pull apart. It needs high yield strength. This means it does not bend easily permanently. It also needs good elongation. This means it can stretch a little without breaking. This toughness is vital. Here is why this matters to you.

1. Safety: High strength means the tube holds the pressure.

2. Long Life: Good oxidation resistance means you do not replace tubes often.

3. Efficiency: Smooth tubes help the heat move better. I always tell my customers to look at the "creep rupture strength." This is a big word. It just means: how long will the tube last under high heat and pulling force? A good tube keeps its strength even when it is very hot. If you ignore this, the boiler will fail early.

Choosing the right high pressure boiler tube requires understanding materials, strict manufacturing processes, and global standards to ensure safety and efficiency for your industrial projects.