High-pressure leaks cause costly delays and safety hazards in your EPC projects. You cannot afford weak links when transporting volatile fluids under extreme stress. Heavy wall seamless steel pipe is designed for extreme pressure and temperature, defined by schedules like SCH120, SCH160, and XXS. It offers superior strength without weld seams, making it critical for oil, gas, and power industries.

We understand the pressure you face. Finding the right materials is not just about ticking a box. It is about the safety of the entire operation. Let us look closer at why this specific pipe is the standard for tough jobs.

Choosing the wrong pipe grade leads to catastrophic failures in the field. You need to know exactly which standard matches your project needs. We classify our heavy wall seamless steel pipe by specific schedules like SCH120, SCH160, and XXS to guarantee they meet strict high-pressure requirements.

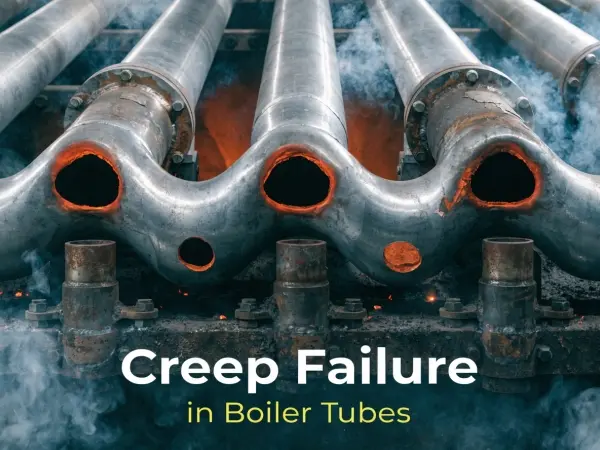

When we talk about heavy walls, we are usually looking at the upper end of the Schedule chart. In my years at Centerway Steel, I have seen many purchase orders that mix up these classifications. It is vital to understand that "heavy" is defined by the ratio of the wall thickness to the outer diameter. We supply pipes in schedules ranging from SCH 100 up to Double Extra Strong (XXS). The material standards are just as important as the thickness. For general high-temperature service, we often use ASTM A106 Grade B. For line pipes in the oil and gas industry, API 5L (Grades B through X70) is the standard. We also work with alloy grades like P11 or P22 for power plants. The chemical composition changes the pipe's ability to handle heat and corrosion. A pipe used for structural piling has different needs than a pipe carrying high-pressure steam. We make sure every heat number is tracked. This ensures that the pipe you install can actually handle the bar pressure listed in your design documents.

| Attribute | Specification Details |

|---|---|

| Wall Thickness Schedules | SCH 100, SCH 120, SCH 140, SCH 160, XXS |

| Common Standards | ASTM A106, ASTM A53, API 5L, ASTM A335 |

| Material Grades | Gr. B, X42, X52, X60, X70, P11, P22, P91 |

| Size Range (OD) | 1/2 inch to 48 inches |

| Certifications | ISO 9001, CE, DNV, API 5L |

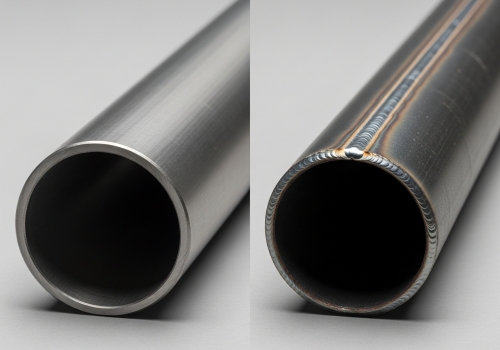

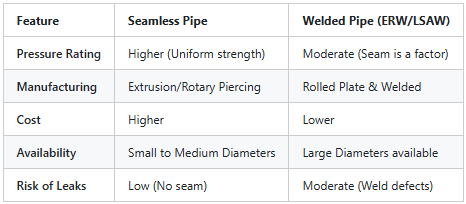

Welded seams create potential weak points that might crack under extreme stress or vibration. You want to eliminate risk in critical infrastructure. Seamless pipes have no welded joints, offering uniform strength and higher pressure ratings compared to welded alternatives like ERW or LSAW.

In the world of pipeline engineering, a chain is only as strong as its weakest link. In a welded pipe, that link is the seam. Even with advanced testing like X-rays, the heat-affected zone around a weld can behave differently than the rest of the metal. This is why heavy wall seamless steel pipe is the preferred choice for the most demanding environments. The manufacturing process makes the difference. We make seamless pipes by piercing a solid steel billet while it is hot. This creates a uniform tube shell. There is no joining of materials. This results in consistent strength around the entire circumference of the pipe. Welded pipes (ERW or LSAW) start as a flat plate. They are rolled and fused. While welded pipes are cheaper and available in larger diameters, they generally have lower pressure ratings. I remember a client in the chemical sector who tried to save money by using heavy-wall welded pipe for a high-vibration line. The seam eventually developed a fatigue crack. They switched to our seamless products, and the issue disappeared. For high pressure, high temperature, or corrosive fluids, seamless is the safer investment.

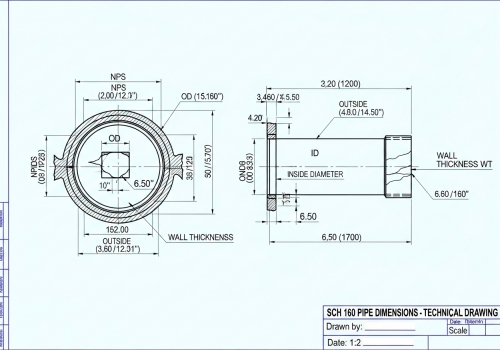

Estimating logistics and support structures requires accurate data on pipe weight and thickness. You need precise charts to plan your shipping and installation. Schedule 160 pipes increase in wall thickness as the diameter grows, directly impacting the internal flow area and the total weight per meter.

Understanding the "Schedule" system is tricky for some new engineers. It is not a fixed thickness. As the pipe gets wider (larger NPS), the wall must get thicker to hold the same pressure. For example, a 2-inch SCH 160 pipe handles pressure differently than a 24-inch SCH 160 pipe. This affects the inside diameter (ID). Since the Outside Diameter (OD) is fixed for compatibility with fittings, a thicker wall means a smaller hole in the middle. There is also a common confusion between SCH 160 and XXS (Double Extra Strong). They are not always the same. For smaller sizes (1/2 inch to 6 inches), XXS is actually thicker than SCH 160. However, for larger sizes (8 inches and up), SCH 160 often becomes thicker than XXS. We help our customers calculate the exact weight for logistics. Heavy wall pipes are incredibly dense. A single length of large-diameter heavy wall pipe can weigh several tons. This impacts how many pipes you can load into a container and what cranes you need on-site. Below is a reference table for some common sizes we supply.

| NPS (Inch) | OD (mm) | SCH 160 Thickness (mm) | Weight (kg/m) |

|---|---|---|---|

| 1/2" | 21.3 | 4.78 | 1.95 |

| 1" | 33.4 | 6.35 | 4.24 |

| 2" | 60.3 | 8.74 | 11.1 |

| 4" | 114.3 | 13.5 | 33.5 |

| 6" | 168.3 | 18.3 | 67.6 |

| 8" | 219.1 | 23.0 | 111.3 |

| 10" | 273.1 | 28.6 | 172.3 |

| 12" | 323.9 | 33.3 | 238.8 |

You need to know if these pipes can withstand the specific environment of your project site. Quality control is the only way to prevent failure. Heavy wall pipes are essential in power generation, offshore drilling, and hydraulic systems, where we verify quality through rigorous third-party inspections.

The applications for heavy wall seamless steel pipe are vast but specific. We supply these mainly to the energy sector. In thermal power plants, main steam lines operate at critical temperatures and pressures. Only a heavy wall pipe can contain that steam without bursting. In the oil and gas industry, specifically in deep-sea drilling, the external pressure from the ocean depth combined with the internal pressure of the oil requires extreme wall thickness. We also see these used in hydraulic pillars for construction equipment and high-pressure vessels. Quality assurance is not optional here. At Centerway Steel, we adhere to ISO 9001 standards. Every pipe goes through testing. This includes hydrostatic testing (pressurizing the pipe with water), ultrasonic testing (checking for hidden cracks), and visual inspection of the bevels and surface. We welcome third-party inspectors like SGS or TUV to our factory. I often tell my customers: "The paper certificate is good, but the physical test is better." We ensure the chemical analysis matches the heat number on the steel. Whether you are building a refinery in the Middle East or a power station in Asia, the pipe must perform.

We provide reliable heavy wall seamless steel pipe to meet your toughest project demands. From SCH 160 to XXS, our quality-tested products ensure safety and efficiency in every installation.