Sourcing reliable piping for large-scale EPC projects can be a nightmare of quality issues and unexpected delays. I know you want to avoid costly shutdowns and ensure your project runs smoothly without budget overruns. A seamless carbon steel pipe is a hollow cylinder produced from a solid billet without any welding seams. It offers superior strength and pressure resistance compared to welded options, making it the ideal choice for high-pressure oil, gas, and steam industries requiring maximum durability and safety.

Many purchasing managers get confused by the technical specifications and the sheer volume of grades available in the market. It is easy to feel overwhelmed when you have a tight deadline and a strict budget. Let me break it down for you so you stop worrying about making the wrong choice and start confident procurement.

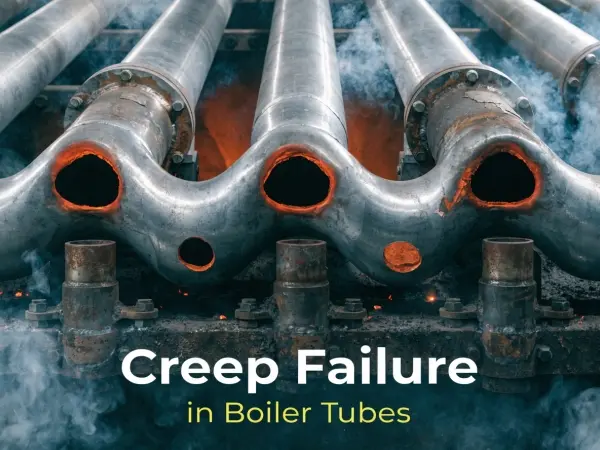

You constantly worry about pipe failure at the weld line during high-pressure operations. These weak points are the biggest risk to your project's safety. Seamless manufacturing eliminates this risk entirely. Seamless pipes start as solid steel bars, not flat plates. Manufacturers heat these billets and push a hole through the center. This creates a uniform structure with no seam, allowing the pipe to withstand significantly higher pressure and temperature than welded alternatives.

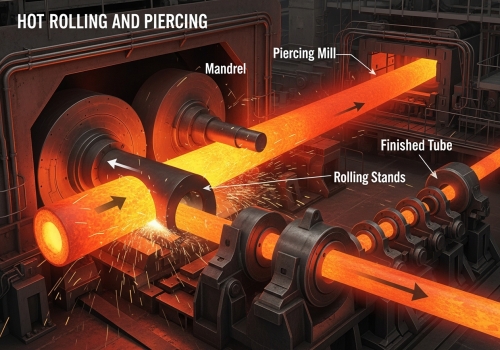

To truly understand the value of a seamless carbon steel pipe, we must look at how we make it. Unlike welded pipes, which start as a flat sheet that we roll and weld, seamless pipes begin as a solid round steel billet. I have seen this process many times in our factory, and it is impressive. We heat the billet to extreme temperatures and then drive a mandrel through the center to create the hollow shape. This process is called "piercing." Because there is no weld seam, the pipe has the same strength at every point around its circumference. In my experience working with EPC companies, this is vital. A welded pipe has a heat-affected zone near the seam that can be a weak spot. A seamless pipe does not have this issue. This makes it perfect for the high-pressure applications you design in CAD, such as boiler tubes or hydrocarbon transport lines. We can finish these pipes in two ways: hot finished or cold drawn. Hot finished pipes are cost-effective and work well for general purposes. However, if your engineers need very tight tolerances and a smooth surface finish, I always recommend cold drawn pipes. They go through an extra sizing process to ensure exact dimensions. This reliability is why the seamless carbon steel pipe remains the standard for critical industrial infrastructure.

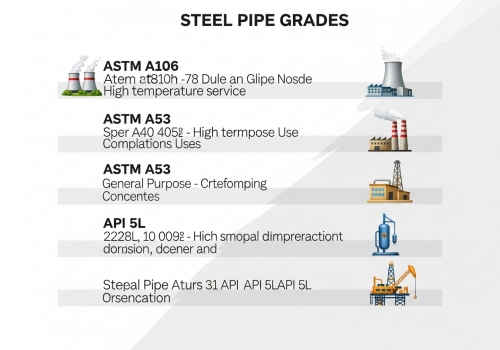

Choosing the wrong grade leads to rapid corrosion, leaks, or even catastrophic bursts. You cannot afford to guess when dealing with volatile chemicals or high-pressure steam systems. The right grade depends entirely on temperature, pressure, and the fluid you are transporting. Common grades like ASTM A106 handle high heat, while API 5L is the standard for oil and gas pipelines. Matching the grade to the environment prevents accidents and extends the lifespan of your equipment.

As a purchasing manager, you know that "carbon steel" is a broad term. To get the best value and performance, we must look at the specific grades. In my 28 years with Centerway Steel, I have seen that selecting the correct grade is the best way to save costs in the long run. You do not want to pay for a high-temperature grade if you are just moving water, but you definitely do not want a water pipe carrying hot oil. Here is a breakdown of the most common grades we supply to global EPC projects: ASTM A106 (High Temperature) This is the workhorse for refineries and power plants. If your project involves high-temperature fluids or gases, this is likely what your engineers specified. It holds up incredibly well under heat. ASTM A53 (General Purpose) This grade is versatile. We supply this often for structural support, air lines, or low-pressure fluid transport. It is available in both seamless and welded forms, but the seamless version offers better peace of mind for pressure systems. API 5L (Line Pipe) If you are moving oil, gas, or water over long distances, this is the specification you need. It focuses on strength and toughness. For sour service (environments with H2S), we provide specific API 5L grades that resist corrosion cracking. ASTM A333 (Low Temperature) Do not overlook the temperature rating. If your project is in a freezing environment, standard steel can become brittle and shatter. A333 is treated to handle temperatures as low as -45°C or even lower.

| Grade | Primary Application | Temperature Range | Key Feature |

|---|---|---|---|

| ASTM A106 | Refineries, Boilers | Up to 750°F | Excellent Heat Resistance |

| ASTM A53 | Steam, Water, Air | Up to 550°F | General Purpose & Structural |

| API 5L | Oil & Gas Pipelines | Varies by Class | High Tensile Strength |

| ASTM A333 | Cryogenics / Arctic | Down to -50°F | Impact Resistance in Cold |

By understanding these differences, you can source the exact seamless carbon steel pipe your team needs without overpaying for unnecessary specs or risking under-specifying critical lines.

Bad quality leads to site rejection, project delays, and damaged reputations. You cannot afford the headache of re-ordering materials while your construction team waits idly. Rigorous testing is the only way to guarantee performance and safety. We rely on hydrostatic testing, ultrasonic detection, and third-party inspections like SGS or BV. This ensures every pipe meets international standards and protects your project’s integrity before it ever leaves the factory.

I know that for a professional like you, trust is good, but verification is better. At Centerway Steel, we believe that quality control is the most important part of our service. Since we integrate production and sales, we have full control over the inspection process. A seamless carbon steel pipe might look perfect on the outside, but we need to know what is happening on the inside. We use a series of non-destructive tests (NDT). First, we perform a hydrostatic test. We fill the pipe with water and pressurize it to a level higher than its operating limit. If it holds, we know it is safe. Next, we use ultrasonic or X-ray testing to look for hidden cracks or air pockets inside the steel wall that the eye cannot see. Surface finish is also a major factor in quality. Carbon steel will rust if left untreated. Depending on your project's location—whether it is an offshore rig or a desert pipeline—we apply different coatings. We offer 3LPE (3-layer polyethylene), FBE (Fusion Bonded Epoxy), or simple galvanization. These coatings act as a shield, extending the service life of the pipe significantly. We also welcome third-party inspectors. I have worked with inspectors from SGS, DNV, and TUV many times. We provide them with full access to verify that our dimensions, wall thickness, and chemical composition match your requirements exactly. This transparency is why we have partners in over 100 countries. We want you to feel completely safe when you sign that purchase order.

Choosing the right pipe requires balancing pressure needs, temperature constraints, and budget. By selecting the correct seamless grade and insisting on rigorous testing, you ensure project safety and efficiency.