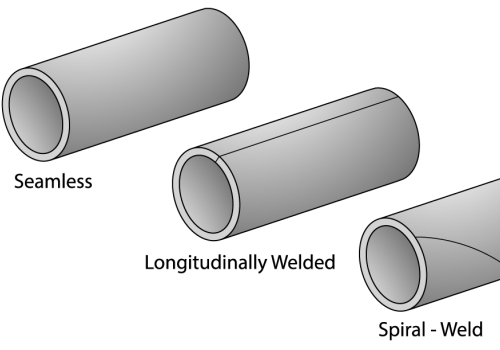

Boiler failures cause massive downtime and safety risks for EPC projects. You cannot afford a burst pipe when dealing with high-pressure steam in a power plant. A seamless alloy pipe for boiler applications is the standard choice because it withstands high temperatures and extreme pressure better than welded alternatives. These pipes have no seam, which means there is no weak point for leaks or explosions. They offer superior resistance to oxidation and corrosion in harsh industrial environments.

We need to understand why these materials are so important. If you choose the wrong pipe, the whole system might fail. Let me explain the details below.

You might think that welded pipes are cheaper and good enough. However, when safety is the main goal, cutting costs on materials can lead to disaster. Seamless steel tubes are the only option for high-pressure equipment. They have a uniform structure that handles stress evenly, unlike welded pipes which can split at the seam under extreme pressure.

The Critical Difference in Performance I have been in this industry since 1996. I have seen how materials behave in the field. Industrial boiler tubes work in very hard conditions. They face high heat and high pressure every day. The flue gas is hot, and the water vapor is corrosive. The tubes must be tough. Seamless steel pipes are made from a solid round steel billet. We heat it and push or pull it over a form until the steel is shaped into a hollow tube. This means there are no welded joints. A welded joint is often the weakest part of a pipe. Even with modern X-ray testing, a weld can have tiny defects. In a boiler, the pressure can be higher than 2Mpa. Welded pipes are usually for low pressure. For anything high-pressure, we must use a seamless alloy pipe for boiler systems. The wall thickness is also easier to control in seamless pipes. We can make them very thick for extra strength. Although the cost is higher, the safety is much better. You do not want to risk a shutdown. Modern welding is getting better, yes. Some low-pressure boilers use welded pipes now. But for the critical heating surfaces, seamless is still the king. It provides the structural stability that you need.

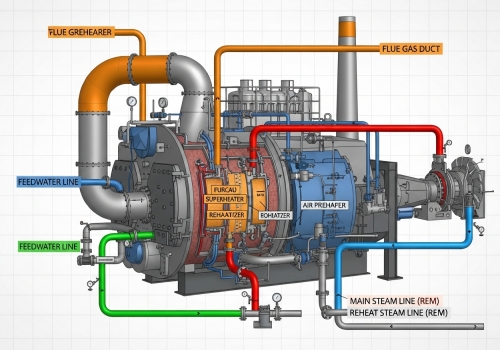

A boiler is not just a big tank of water. It is a complex system of veins and arteries. You need to know which pipe goes where. The four major pipelines are the High-pressure water supply, Main steam pipe, Reheat steam cold section, and Reheat steam hot section. Each one has a specific job.

Understanding the Function of Each Pipeline In my experience working with EPC companies, I see that designers need to match the specific pipe to the specific section. We cannot just use one type of pipe for everything. Here is a breakdown of the four major lines.

4. Reheat steam hot section pipeline: This pipe takes the steam that has been heated up again. It goes from the reheater outlet back to the turbine. We often use a seamless alloy pipe for boiler areas like the Main Steam and Reheat sections. This is because the temperature is very high here. Carbon steel might get soft. Alloy steel stays strong. To help you understand, I have made this simple table:

| Pipeline Name | Medium Transported | Critical Stress Factor | Recommended Material Type |

|---|---|---|---|

| Water Supply | High-pressure Water | Hydraulic Pressure | Carbon or Low Alloy Seamless |

| Main Steam | Superheated Steam | Thermal & Pressure | High Alloy Seamless |

| Reheat Cold | Exhaust Steam | Moderate Temp/Pressure | Carbon/Alloy Seamless |

| Reheat Hot | Reheated Steam | High Thermal | High Alloy Seamless |

Buying a pipe is easy, but getting a pipe with a perfect surface is hard. Many suppliers ignore the finish, but this causes problems later. We ensure that pickling, passivation, and grinding are done correctly. This removes scratches and weld defects that could turn into rust points or cracks.

The Importance of Surface Treatment When you buy pipes for a project, you look at the specs. But you must also look at the surface. I often see problems with surface treatment in the market. First, the surface can be uneven. This happens when the factory only cleans the weld area but not the whole pipe. It looks bad. More importantly, it hides defects. We prefer to pickle the whole pipe. This makes the surface uniform. Second, scratches are a big issue. A seamless alloy pipe for boiler use must be smooth. During processing, machines can scratch the pipe. If we do not remove these scratches, they become "stress risers." This means stress builds up there. It can lead to cracks. Also, for stainless or alloy pipes, iron dust from other tools can stick to the surface. If this iron rusts, it eats into the alloy pipe. This is called electrochemical corrosion. Third, we have to talk about repair marks. Sometimes, a pipe has a small defect. Workers fix it by grinding. If they grind it too much, the wall gets thin. The surface gets rough. At Centerway Steel, we are strict about this. We follow ISO 9001 standards. If a defect is too deep, we reject the pipe. We do not just patch it up. We make sure the pickling is complete. This removes all the dirt and iron dust. It creates a passive layer that protects the steel.

Industrial boilers demand reliability, which is why a seamless alloy pipe for boiler systems is the superior choice for high-pressure and high-temperature environments. From the main steam lines to the water supply, the integrity of these pipes ensures your project runs safely. At Centerway Steel, we provide the quality assurance and one-stop service you need to avoid costly failures.