Finding the right piping materials for large projects is stressful. You worry about safety, costs, and if the materials will truly last under pressure. Schedule 40 seamless steel pipe is the most common pipe specification used in construction and industrial sectors. It represents a specific wall thickness standard defined by ASME, offering a perfect balance between structural strength and cost. It handles high pressure better than welded pipes because it has no weak seam.

Many of my clients ask me if this specification is right for their specific needs. Let's look at the details so you can make the right buying decision.

The numbers on pipe charts can often be very confusing. Do they refer to millimeters, inches, or a specific pressure rating you need to know? "Schedule" (SCH) is not a direct measurement of thickness in millimeters. It is a standard identifier from the ASME B36.10M code. Schedule 40 seamless steel pipe refers to a specific wall thickness series that changes relative to the pipe's overall diameter.

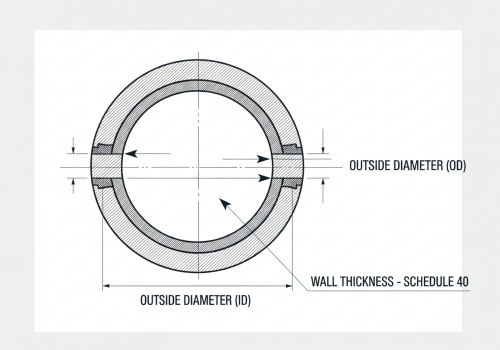

I have worked in the steel industry since 1996, and I see many people get confused by the "Schedule" system. It is important to understand that Schedule 40 does not mean the wall is 4.0mm thick. It is a classification. For any given pipe size, the Outside Diameter (OD) always stays the same. This allows pipes to fit into standard supports and valves. However, as the Schedule number goes up (like from 40 to 80), the wall gets thicker. Since the outside stays the same, the extra thickness grows inward, making the hole in the middle (the Inside Diameter) smaller. Schedule 40 is the "standard weight" for piping. It is the most popular choice because it is versatile. It is thick enough to hold significant pressure but not so thick that it becomes too heavy or expensive for general use. In the past, people said "40" meant it could hold 40 kilograms of pressure, but today we rely on strict ASME tables. When we look at the manufacturing, Sch40 ensures high dimensional accuracy. This means when your team is welding or fitting these pipes on-site, the parts fit together perfectly. This saves you time and labor costs during installation.

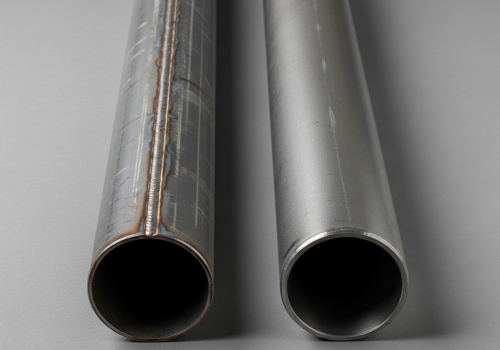

Welded pipes are often cheaper, which tempts many purchasing managers. But can you really trust a welded seam when safety is your top priority? Seamless pipe is made from a solid round steel 'billet' that is heated and pushed or pulled over a form. This process means schedule 40 seamless steel pipe has no welded seam, giving it uniform strength around the entire cylinder and higher resistance to corrosion.

In my years of supplying global projects, I have seen welded pipes fail where seamless pipes succeed. The difference lies in the production method. A welded pipe (ERW) starts as a flat sheet of steel. It is rolled into a tube and the edges are welded together. Even with high-quality manufacturing, that weld line is always the weakest point. It is more likely to crack under high pressure or corrode faster than the rest of the pipe. Seamless pipe is different. We make it by piercing a hole through a solid bar of hot steel. There is no seam. This gives the pipe "isotropic" strength, meaning it is equally strong in all directions. Here are the key benefits I tell my clients:

1. Appearance: It looks better. The surface is smooth without the visual scar of a weld.

2. Pressure: It can withstand higher pressures (roughly 20% higher than welded pipe of the same size).

3. Risk: It removes the risk of a bad weld passing inspection but failing later. If you are building a pipeline for water, gas, or chemical fluids, the extra cost of seamless pipe is an investment in safety. It acts as insurance against leaks and bursts.

Guessing measurements can lead to disastrous installation errors. You need the exact data to calculate shipping weights and fit-up requirements accurately. The dimensions for schedule 40 seamless steel pipe vary based on the Nominal Pipe Size (NPS). The table below outlines the standard measurements in both inches and millimeters, helping you plan your logistics and engineering designs with precision. As a supplier, I know that logistics are just as important as the product itself. You need to know the weight to book the right shipping containers. You need the exact wall thickness to choose the right welding procedure. Below is the standard data chart we use at Centerway Steel. This is based on international standards. You will notice that for smaller pipes (like 1/8 inch to 10 inches), the Schedule 40 thickness is the same as "Standard Weight" (STD). Here is the breakdown for common sizes:

| Nominal Size (Inches) | OD (mm) | Wall Thickness (mm) | Weight (kg/m) |

|---|---|---|---|

| 1/2 | 21.3 | 2.77 | 1.27 |

| 3/4 | 26.7 | 2.87 | 1.69 |

| 1 | 33.4 | 3.38 | 2.50 |

| 1 1/4 | 42.2 | 3.56 | 3.39 |

| 1 1/2 | 48.3 | 3.68 | 4.05 |

| 2 | 60.3 | 3.91 | 5.44 |

| 3 | 88.9 | 5.49 | 11.29 |

| 4 | 114.3 | 6.02 | 16.07 |

| 6 | 168.3 | 7.11 | 28.26 |

| 8 | 219.1 | 8.18 | 42.55 |

| 10 | 273.0 | 9.27 | 60.31 |

| 12 | 323.8 | 10.31 | 79.73 |

| 14 | 355.6 | 11.13 | 94.55 |

When you look at this table, pay attention to the weight per meter. This helps us calculate the total tonnage for your order. Also, note that for very large pipes (over 12 inches), Schedule 40 remains a popular choice because it maintains structural integrity without becoming impossibly heavy to lift and install.

Schedule 40 seamless steel pipe is the reliable, high-strength choice for serious industrial projects. It offers superior pressure resistance and dimensional accuracy, making it perfect for oil, gas, and construction sectors.