Finding the right pipeline supplier is stressful. You worry about delays, poor quality, and high costs that hurt your project's bottom line. Seamless steel pipe is made by heating a solid steel billet and piercing it to create a hollow shell. This shell is then rolled and stretched to the desired diameter and wall thickness without any welding seams. This process ensures uniform strength and high pressure resistance.

To choose the right manufacturer, you must understand the production method.

You need precise dimensions for smaller pipes in your construction projects. The Mandrel Mill process is the standard solution for these sizes. The Mandrel Mill process creates seamless pipes, usually between 1 to 6 inches. We heat a solid billet, pierce it, and insert a mandrel bar. Rolls reduce the wall thickness continuously.

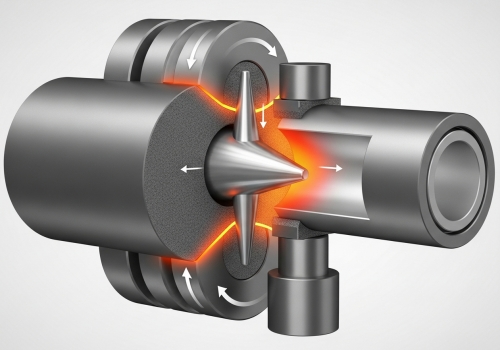

I want to explain this process in detail. It is the most common method we use at Centerway Steel for small to medium sizes. The process starts with a solid round steel billet. We call this the "billet." We place this billet into a rotary hearth furnace. The temperature creates a glowing red metal. It reaches about 1,300°C. Next comes the piercing stage. A machine forces a hole through the center of the hot steel. It is now a hollow shell. But the walls are too thick. This is where the Mandrel Mill is vital. We insert a long bar, called a mandrel, inside the shell. The machine passes the shell through a series of curved rollers. These rollers sit at 90-degree angles to each other. They squeeze the steel against the mandrel bar inside. This reduces the wall thickness very evenly. The pipe is still not finished. It goes to a reheating furnace. Then, it enters a stretch-reducing mill. This machine pulls and squeezes the pipe to hit the exact final diameter. We cut it to length. This method is very fast. It produces long lengths of pipe. It provides excellent surface quality. This is exactly how is seamless steel pipe made for sizes typical in standard construction and plumbing. We see this used often in the projects we supply in Southeast Asia and the Middle East. The efficiency of this method helps us keep costs down for your EPC contracts.

Large infrastructure projects often require pipes with diameters bigger than 6 inches. The Plug Mill process handles these heavier requirements. This process targets pipes from 6 to 16 inches. It also pierces a heated billet but uses an internal plug and a reeling machine to smooth the walls and ensure roundness.

The Mannesmann Plug Mill process is distinct from the Mandrel method. It creates larger, thick-walled tubes. We start with a much heavier steel ingot. Sometimes these weigh up to two tons. We heat them to the same high temperature of 1,300°C. The piercing step happens first. But here, we use a rotary elongator. This expands the hole and creates a short, thick tube. We call this a "bloom." A worker or machine inserts an internal plug into the bloom. The diameter of this plug matches the final inside diameter you need. The bloom goes between the rolls of the Plug Mill. The rolls spin and press the steel over the plug. This thins the wall. There is a critical step here. We rotate the tube 90 degrees for each pass. This rotation is vital. It ensures the tube is perfectly round. It removes uneven spots in the wall thickness. After this, the tube goes to a reeling mill. This machine burnishes the inside and outside surfaces. It makes them smooth. Finally, a sizing mill ensures the dimensions are correct. This method is slower than the Mandrel process. But it is necessary for the large, heavy pipes used in oil and gas lines. This explains how is seamless steel pipe made for heavy-duty applications where pressure resistance is the main concern.

Rolling the steel is only half the job. You need pipes that meet strict international safety standards. Finishing involves straightening, heat treatment, and rigorous testing. We perform hydrostatic tests and non-destructive inspections to guarantee the pipe will not fail under pressure.

Quality control is the most important part of my job as a supplier. At Centerway Steel, we do not ship pipes straight from the rolling mill. The pipe is soft and not straight after hot working. We put it through a straightening machine. Then, we perform heat treatment. This adjusts the mechanical properties of the steel. It makes the steel strong and tough. We cut the pipes to the length you ordered. Then, the testing begins. This is crucial for you as a purchasing manager. We use Hydrostatic testing. We fill the pipe with water and pressurize it. We check for leaks. We also use ultrasonic or X-ray testing. These are non-destructive tests (NDT). They find hidden cracks inside the steel wall. I have listed the differences between the two main production methods below. This table helps you decide which process fits your specific order list.

| Feature | Mandrel Mill Process | Mannesmann Plug Mill Process |

|---|---|---|

| Typical Size Range | 1 to 6 inches (25-150 mm) | 6 to 16 inches (150-400 mm) |

| Starting Material | Solid Round Billet | Heavy Steel Ingot |

| Wall Reduction Tool | Long Mandrel Bar | Internal Plug |

| Key Mechanism | Continuous Rolling | Rolling with 90° Rotation |

| Production Speed | High / Fast | Moderate |

| Main Application | Standard Construction, Small Lines | Large Diameter Oil & Gas Lines |

Understanding these final steps completes the picture of how is seamless steel pipe made. It ensures you get a product that lasts for decades. We inspect every single piece. We define ourselves by this quality. Whether you need standard sizes or large heavy-wall pipes, knowing these details helps you negotiate better and secure the best materials for your company.

Seamless pipe manufacturing involves heating, piercing, rolling, and strict testing. This ensures high-pressure tolerance and reliability for your construction projects. We provide this quality directly from China to you.