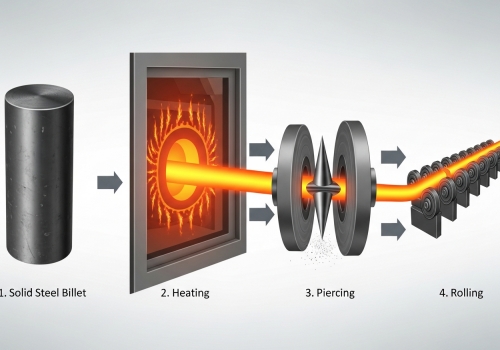

Buying the right materials for large construction projects causes high stress for purchasing managers. A single material failure creates delays and ruins your reputation. You must understand the true definition of seamless pipes to avoid costly mistakes. The seamless steel pipe meaning refers to a tube manufactured without a welding seam. It starts as a solid round steel billet. We heat this billet and cast it over a piercing rod. This process creates a hollow shell with uniform structural strength. It handles high pressure better than welded alternatives.

Many suppliers confuse buyers with complex technical jargon or vague descriptions. I see this often in my dealings with international partners. You need clear facts to make the best sourcing decision for your company. I will explain the details simply below.

Manufacturing defects in pipeline materials can weaken entire building structures. You cannot afford a structural failure in an EPC project that you supervise. We control the production process from heating to cooling to prevent this. The manufacturing method defines the quality. We divide production into hot-rolled and cold-drawn methods. Hot rolling happens above the recrystallization temperature for bulk production. Cold drawing happens at room temperature for high precision. Both methods prevent the weak points usually found in welded seams.

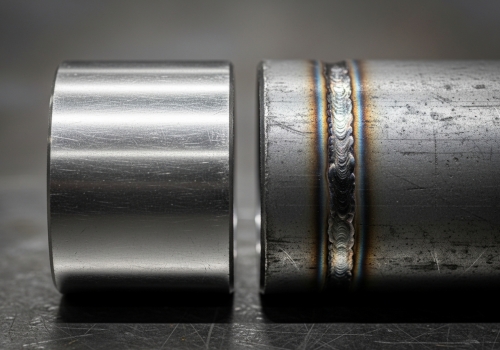

To truly grasp the seamless steel pipe meaning, we must look at the raw material. The process begins with a solid steel bar. We call this a billet. It has no gaps and no joints. We heat this billet to extreme temperatures. It becomes soft and malleable. We then force it over a piercing rod. This transforms the solid bar into a hollow tube. This differs completely from welded pipes. Welded pipes start as flat plates. Machines curl the plate and weld the edges. That weld is always a potential weak point. Seamless pipes have no such weakness. The metal structure remains continuous around the entire circumference. We categorize these pipes based on temperature during processing. Hot-rolled pipes form while the steel is very hot. This makes them easier to shape. It is good for large diameters and thick walls. Cold-drawn pipes undergo processing after the steel cools down. We pull the pipe through a die to shrink it. This improves the surface finish. It also makes the dimensions very precise. German engineers often prefer cold-drawn pipes for machinery because the size is exact. This variety allows us to meet specific needs for any construction or oil project.

Welded pipes often split or crack under high internal pressure. A burst pipe shuts down the whole site and endangers workers. Seamless pipes offer uniform strength and keep your operations safe. Seamless pipes resist high pressure and corrosion because they lack a weld line. The metal is dense and uniform throughout the pipe body. This structure eliminates the risk of interlayer tearing or weld shrinkage. They are safer for transporting oil, gas, and steam in complex networks.

The structural integrity of your project depends on the materials you select. I have seen projects suffer because someone chose a cheaper welded pipe for a high-pressure application. The seamless steel pipe meaning implies reliability. The cross-section of the steel is more complex and dense. This density improves corrosion resistance. When we produce hot-rolled seamless pipes, the process refines the grain structure of the steel. It crushes the cast microstructure. This eliminates small defects inside the metal. The steel becomes compact. Its mechanical properties improve. It is no longer isotropic to a certain extent. However, you must know the trade-offs. Hot-rolled pipes might have uneven cooling. This causes residual stress. The dimensions are not always perfect. Cold-rolled pipes solve this. They have high dimensional accuracy. The surface is smooth and shiny. But, cold rolling can reduce the torsion resistance slightly. I have created a table to help you compare the two types effectively:

| Feature | Hot-Rolled Seamless Pipe | Cold-Drawn/Rolled Seamless Pipe |

|---|---|---|

| Processing Temp | Above recrystallization temp | Room temperature |

| Precision | Lower accuracy | High dimensional accuracy |

| Surface Finish | Rougher, may have oxide scale | Smooth, clean surface |

| Wall Thickness | Typically thicker (2.5mm - 75mm) | Can be very thin (<0.25mm) |

| Main Advantage | improved mechanical properties | High precision and aesthetics |

| Typical Use | Structural, fluid transport | Machinery, hydraulic systems |

Not every pipe fits every job in the construction industry. Using the wrong grade wastes your budget and causes installation headaches. You need to match the specific pipe capabilities to the application requirements. We use these pipes in boilers, hydraulic systems, and oil refineries. They handle mechanical stress and vibration very well. Their uniform shape makes them easy to install in tight spaces. This reliability helps designers and purchasing managers sleep better at night. The application of these pipes is vast. It goes beyond simple fluid transport. We see them in engineering and construction frequently. They act as structural supports because they resist bending. In my experience with Centerway Steel, we supply these for thermal power generation. High-pressure boilers need tubes that will not fail. The seamless nature prevents leaks even when the steam pressure is immense. We also supply them for mechanical tubing. This includes parts for cars, ships, and heavy machinery. Another key area is the oil and gas sector. Casing pipes protect the wellbore. Tubing transports the crude oil. These environments are harsh. The pipes face corrosion from the earth and pressure from the depth. A welded pipe is risky here. A seamless pipe is the standard choice. For my clients in Germany and Europe, the precision of cold-drawn pipes is vital. They use them for hydraulic cylinders. The inner surface must be perfect. Any roughness destroys the seals. We ensure our products meet these strict standards. We hold ISO and CE certifications. This guarantees that the pipe you buy matches the high performance you expect.

Understanding the seamless steel pipe meaning helps you buy better materials. These pipes offer unmatched strength and safety for your EPC projects. I am here to help you source them efficiently.