Finding reliable steel pipes is stressful when project deadlines approach and budgets are tight. Poor quality materials risk safety, cause delays, and can ruin your reputation in the construction industry. Seamless tube manufacturing involves piercing a solid steel billet to create a hollow shell, followed by rolling to reduce diameter and wall thickness. This method produces pipes with high strength and pressure resistance, making them essential for oil, gas, and construction industries where reliability is paramount.

Many buyers overlook the technical steps that determine pipe quality. I want to show you exactly how we turn raw steel into the high-performance products you need. This knowledge helps you make smarter purchasing decisions.

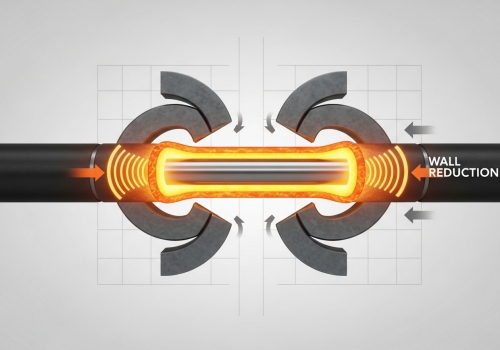

You need specific sizes for your pipelines, but accuracy often varies between suppliers. Inconsistent wall thickness causes major installation headaches and can lead to structural failures in high-pressure environments. The Mandrel Mill process heats a round billet and pierces it. We insert a mandrel bar and roll the shell to reduce thickness continuously. This method is perfect for producing smaller, high-performance pipes commonly used in standard construction and transport networks.

At Centerway Steel, we see seamless tube manufacturing as a precise science. The Mandrel Mill process is the gold standard for producing pipes with outside diameters typically ranging from 25 mm to 150 mm (1 to 6 inches). It starts with a solid round billet. We heat this billet in a rotary hearth furnace to about 1,300°C. Once it is hot, a piercer creates a hole through the center. This is where the magic happens. We insert a mandrel bar into the hollow shell. Then, the assembly passes through a series of curved rollers. These rollers are set at 90-degree angles to each other. They work together to reduce the wall thickness continuously. This is different from other methods because the reduction is very smooth and uniform. After rolling, we reheat the mother tube and pass it through a stretch-reducing mill. This gets the diameter down to the exact size you need. This process is critical for your projects because it ensures tight tolerances. When you are building a complex pipeline network, every millimeter matters. The Mandrel Mill process gives the pipe a superior surface finish and consistent wall thickness. This means fewer rejections at the site and faster installation for your team.

| Stage | Action | Benefit for the Buyer |

|---|---|---|

| Heating | Billet heated to 1,300°C | Ensures steel ductility for forming. |

| Piercing | Solid round becomes a hollow shell | Creates the seamless structure (no welds). |

| Mandrel Rolling | Curved rollers reduce wall thickness | guarantees uniform thickness and strength. |

| Stretch Reducing | Multi-stand mill adjusts diameter | Provides exact custom sizes for your design. |

Large projects often require heavy-duty pipes that must withstand immense pressure and heavy loads. Finding suppliers who can consistently produce these large diameters with high integrity is difficult. This process takes a larger steel ingot and pierces it into a thick-walled bloom. A plug forces the steel through rolls to thin the walls and expand the diameter. It is the standard method for creating large, heavy-wall pipes essential for major infrastructure.

When your project demands larger pipes, typically between 150 mm and 400 mm (6 to 16 inches), the machinery must change. We rely on the Mannesmann Plug Mill process for this range. This is a robust method within seamless tube manufacturing. We start with a much larger steel ingot, which can weigh up to two tons. Like the mandrel process, we heat it to extreme temperatures. However, after piercing, the hole is enlarged on a rotary elongator. This creates a short, thick-walled tube we call a "bloom." The key tool here is the internal plug. We force a plug, which matches the finished inside diameter, through the bloom. At the same time, the bloom passes between the plug mill rolls. These rolls spin the tube and reduce the wall thickness. We rotate the tube 90 degrees for each pass. This rotation is crucial. It ensures the pipe is perfectly round. If we did not rotate it, the pipe might end up oval, which would be a disaster for your connections. After the plug mill, the pipe goes through a reeling machine. This burnishes the inside and outside surfaces, making them smooth. Finally, a sizing mill sets the exact dimensions. For an EPC company, this process is vital. It allows us to produce heavy-wall pipes that can handle the stress of high-pressure oil and gas transport or structural support in buildings.

| Feature | Mandrel Mill | Plug Mill |

|---|---|---|

| Typical Size Range | 25mm - 150mm (Small/Medium) | 150mm - 400mm (Medium/Large) |

| Starting Material | Solid Round Billet | Large Steel Ingot |

| Key Tool | Long Mandrel Bar | Internal Stationary Plug |

| Primary Advantage | High speed, great surface finish | Handles heavy walls and large diameters |

Manufacturing is only half the battle; hidden defects inside the steel can be disastrous for your project. Ignoring final inspections puts your entire operation and safety record at risk. After the hot working phase, pipes undergo heat treatment, straightening, and rigorous hydrostatic testing. We check for internal flaws using ultrasonic methods to ensure every inch meets international standards like API and ASTM before it leaves our factory.

I know that as a Purchasing Manager, your nightmare is receiving a shipment of pipes that fail on site. That is why the process does not end when the pipe leaves the rolling mill. At Centerway Steel, we believe the finishing line is just as important as the starting line. Once the seamless tube manufacturing phases are complete, the "mother tube" must be treated to lock in its mechanical properties. We cut the tube to length and often perform heat treatment. This relieves the internal stresses caused by the rolling process. If we skip this, the pipe could warp or crack under load. After heat treatment, the pipe goes through a straightener. A curved pipe is useless to you, so we ensure it is perfectly straight. But the most critical part is testing. We do not just look at the pipe; we test it under pressure. We perform hydrostatic testing, where we fill the pipe with water at high pressure to ensure it does not leak. We also use Non-Destructive Testing (NDT) methods like ultrasonic or eddy current testing. These technologies let us see inside the steel walls. We can detect air pockets or cracks that the human eye misses. Since 1996, we have adhered to ISO 9001 standards. We do this to ensure that when our pipe arrives in Germany, or anywhere else, it is ready for work.

· Heat Treatment: Restores the microstructure of the steel for strength.

· Sizing & Straightening: Ensures the pipe fits your specific design prints.

· Hydrostatic Testing: Proves the pipe can hold the required pressure.

· NDT Inspection: Finds hidden flaws to prevent future failures.

Understanding these processes helps you select the right pipe for your specific needs. At Centerway Steel, we combine advanced technology with strict testing to deliver the reliable one-stop solutions your projects require.