Hydraulic systems demand reliability, strength, and precision. At the core of these systems lies the hydraulic seamless pipe, which must withstand high internal pressures, resist fatigue, and maintain dimensional accuracy over long-term use. Two primary manufacturing technologies dominate this field: hot rolling and cold drawing. Understanding these processes is critical for engineers, procurement specialists, and quality managers when selecting the right pipe for high-pressure hydraulic applications.

A hydraulic seamless pipe is a hollow steel tube produced without any weld seam, ensuring uniform strength and excellent pressure resistance. Unlike welded pipes, seamless pipes have no weak points along the circumference, making them ideal for hydraulic cylinders, heavy machinery, and high-pressure fluid transmission.

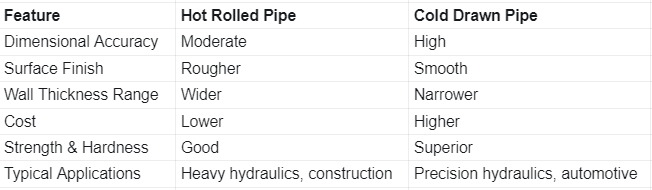

Hot rolling is a process where steel billets are heated above their recrystallization temperature and then rolled into the desired pipe shape.

Hot rolled hydraulic seamless pipes are widely used in industries like construction machinery, mining equipment, and heavy hydraulics where size and strength are prioritized over extreme accuracy.

Cold drawing involves pulling a hot rolled tube through a die at room temperature, significantly improving precision and surface quality.

Cold drawn pipes are preferred in aerospace, automotive hydraulics, and precision engineering applications where accuracy and reliability are critical.

Both hot rolling and cold drawing technologies play essential roles in the manufacturing of hydraulic seamless pipes. If your application requires heavy load-bearing capacity and larger dimensions, hot rolled pipes are the better choice. However, for precision, tight tolerance, and smooth surface requirements, cold drawn pipes offer clear advantages.

Selecting the right process ensures not only the reliability of hydraulic systems but also long-term cost efficiency. When sourcing, always verify compliance with international standards such as ASTM, DIN, or EN to guarantee performance and safety.

If you need high-quality hydraulic seamless pipes, feel free to contact us for a quotation. We will help you find the most suitable, tailor-made products for your project.