You are likely facing delays and rising costs because standard pipes just do not fit your precision machinery. Finding a supplier who can deliver exact dimensions without requiring extra machining work is a constant headache. Seamless cold drawn steel tube is the answer for high-precision applications like hydraulic systems and automotive parts. It offers superior dimensional accuracy, a smooth surface finish, and higher mechanical strength compared to hot-rolled options, which directly reduces your processing time and material waste.

Many purchasing managers I work with struggle to balance the initial purchase price with the final installed cost. You might see a lower price tag on a hot-rolled pipe, but the hidden costs of grinding, turning, and polishing can destroy your budget. Before you sign that next purchase order, I want to show you exactly how this specific tubing can solve your sourcing challenges.

Buying steel pipes is risky if the manufacturer uses poor raw materials or skips essential cleaning steps. You worry about hidden cracks or surface defects that could lead to catastrophic failure once the pipe is installed in your client's system. We eliminate this risk by starting with high-quality carbon or alloy structural steel and using a strict production process. This includes acid pickling to remove impurities, precise cold rolling to shape the pipe, and rigorous testing. This ensures every seamless cold drawn steel tube we produce meets international standards like ISO and ASTM.

I want to take you inside our production philosophy at Centerway Steel. We have been doing this since 1996, and we know that quality starts before the metal even touches the rolling mill. The most basic but critical link is raw material selection. We only source high-quality carbon structural steel or alloy structural steel. If the billet has internal flaws, no amount of processing can fix it. Once we have the right material, we follow a specific sequence to ensure the pipe meets your exact specs:

1. Pickling: We don't just wash the steel; we use acid to remove oxide scale and rust. This is vital. If we leave scale on the billet, it gets pressed into the steel during rolling, creating surface defects.

2. Cold Rolling: We stretch the billet on a cold rolling mill at room temperature. This is where the magic happens. By stretching it cold, we align the grain structure of the steel. This creates a seamless cold drawn steel tube with incredibly precise Outer and Inner Diameters.

3. Testing: We don't guess. We use penetration testing to check for cracks you can't see with the naked eye. We also check physical properties to ensure the pipe can handle the pressure you need it to hold. Here is a quick look at why these steps matter to your bottom line:

| Production Step | What We Do | Benefit to You |

|---|---|---|

| Pickling | Remove oxide and rust | Smooth surface, no clogging in hydraulic systems. |

| Cold Rolling | Stretch at room temp | Tight tolerances, less machining needed. |

| Heat Treatment | Eliminate stress | Pipe won't crack during installation. |

| Final Testing | Check dimensions/defects | You get exactly what you ordered, every time. |

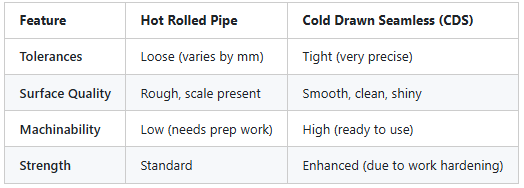

You might be tempted to save money upfront by choosing hot-rolled pipes for your construction or machinery projects. However, the loose tolerances and rough surfaces of hot-rolled steel often force you to spend more money on machining and finishing later. Cold drawing significantly improves the physical properties of the pipe, providing uniform tolerances and excellent straightness. Unlike hot finishing, a seamless cold drawn steel tube requires very little machining allowance. This means you save on labor hours and tool wear, making your overall project more profitable.

Let's look at the real differences. In my 18+ years of experience in this industry, I have seen many engineers try to use hot-rolled pipes for precision jobs. It rarely works out well. Hot-rolled pipes are formed at high temperatures. As they cool down, the metal shrinks unevenly. This leads to variations in size and shape. Cold drawn pipes are different. Because we work them at room temperature, we have total control. We can hold tolerances down to fractions of a millimeter. This is crucial for applications like hydraulic cylinders, where a piston needs to seal perfectly against the tube wall. Here is why switching to cold drawn is a smart move for your budget:

· Mechanical Strength: When we stretch the steel cold, it undergoes "work hardening." The internal grain structure becomes tighter and stronger. This means a cold drawn pipe can often withstand higher pressures than a hot-rolled pipe of the same size.

For high-end machinery, automotive parts like shock absorbers, or aerospace components, the choice is clear. You pay for precision now to save on headaches later.

You need pipes that are hard enough to resist wear but tough enough not to shatter under impact. Getting this balance wrong leads to equipment failure, safety hazards, and expensive downtime for your end-users. Heat treatment is the secret tool we use to customize the steel's internal structure. Through processes like annealing, normalizing, or quenching, we adjust the mechanical properties of the seamless cold drawn steel tube. This ensures the pipe can handle the specific stress, temperature, and wear conditions of your unique environment.

This part of the process is technical, but it is vital for you to understand. After we cold draw the pipe, the metal is very hard because of the stretching process. While hardness is good, it can also make the pipe brittle. If we shipped it to you immediately, it might crack if you tried to bend it. We use different "recipes" in our furnace depending on what you need the pipe to do. We don't just guess; we follow strict protocols.

· Annealing: We heat the pipe and let it cool very slowly. This creates the softest state for the steel. If your project involves bending the tubes into complex shapes or flaring the ends, you want annealed steel. It removes the internal stress so the metal flows instead of breaking.

· Normalizing: We heat the steel and let it cool in still air. This makes the grain structure uniform throughout the pipe. It provides a good balance of strength and toughness. This is the standard for most structural applications.

· Quenching and Tempering: This is for the toughest jobs. We heat the pipe and then cool it rapidly (quenching) in oil or water. This makes the steel extremely hard. Then, we heat it again slightly (tempering) to bring back some flexibility. This is perfect for parts that face high wear, like heavy machinery gears or shafts. We can apply these treatments to match your specific industry needs:

| Application | Recommended Treatment | Why It Works |

|---|---|---|

| Bending/Forming | Annealing | Makes the steel soft and plastic. |

| General Machining | Normalizing | Ensures consistent cutting behavior. |

| High Wear Parts | Quenching + Tempering | Creates a hard, durable surface. |

| Surface Hardening | Carburizing/Nitriding | Adds chemicals to the surface for extreme wear resistance. |

At Centerway Steel, we don't just sell you a pipe off the shelf. We ask you what you are building. Then, we choose the right heat treatment to ensure our product lasts as long as your reputation demands.

We provide high-precision seamless cold drawn steel tubes that maximize your budget by reducing machining time. From strict raw material selection to customized heat treatment, Centerway Steel guarantees the quality and durability you need.