You face constant pressure to ensure safety in your pipelines while keeping costs down. Pipeline failures can be disastrous. How do you balance durability with strict project budgets? The benefits of seamless stainless steel tubes in high-pressure applications stem from their lack of weld seams. This unique structure eliminates weak points, allowing for higher working pressures, superior corrosion resistance, and consistent strength, making them the safest choice for critical industrial infrastructure.

I remember a specific project back in 2005. We were working with a partner in the Middle East for a desalination plant. They initially wanted to use standard welded pipes to save on the upfront budget. I warned them about the pressure fluctuations in their system. Sadly, they faced leaks within six months. This halted their production and cost them double the original savings to fix. That experience taught me a valuable lesson. It is vital to choose the right material from the start. Let me explain why seamless tubes are often that right choice.

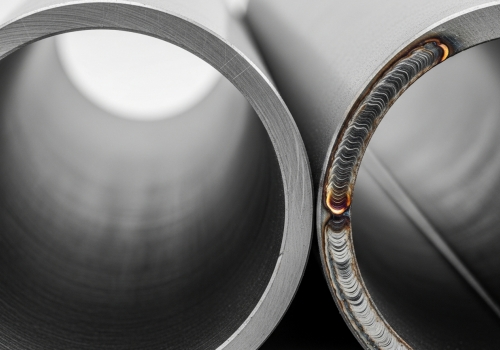

Leaks in high-pressure systems are a nightmare for any project manager. Weak spots in pipes cause downtime. You need a solution that eliminates these risks entirely. Seamless tubes offer uniform strength around the entire circumference. Without a heat-affected zone from welding, they handle significant internal stress better. This is one of the primary benefits of seamless stainless steel tubes in high-pressure applications.

We at Centerway Steel have supplied pipes for over 25 years. We see the difference in the field. The manufacturing process of a seamless tube makes it superior. We start with a solid billet of steel. We heat it and stretch it over a form. There is no welding involved. This means the pipe is one continuous piece of metal. In a welded pipe, the seam is always the weakest link. Even with the best X-ray testing, the weld zone has different physical properties than the rest of the pipe. It creates a point where stress gathers. In high-pressure environments, like oil wells or power plant boilers, this matters. The internal pressure pushes against the pipe wall. If there is a seam, the pressure finds it. Seamless pipes do not have this problem. They have the same strength everywhere. This allows them to withstand much higher pressures. They calculate the "burst pressure" much higher than welded pipes of the same size. For an EPC manager, this means peace of mind. You do not have to worry about a seam splitting when the system spikes in pressure. This reliability is why we see them in critical sectors like nuclear power and deep-sea oil extraction.

| Feature | Seamless Pipe | Welded Pipe |

|---|---|---|

| Structure | Homogeneous, no seams | Heterogeneous, contains a weld seam |

| Pressure Rating | High (20% higher on average) | Lower (limited by weld strength) |

| Weak Points | None | The Heat Affected Zone (HAZ) |

| Safety Factor | Excellent for critical use | Moderate for general use |

Industrial environments are harsh, eating away at standard materials quickly. Replacing corroded pipes disrupts operations. You need materials that last longer in aggressive settings. Yes, they can. The uniform microstructure of seamless steel provides excellent resistance to oxidation and chemical attacks. Whether it is cryogenic LNG or superheated steam, these tubes maintain their mechanical properties, ensuring long-term reliability.

When we talk about the benefits of seamless stainless steel tubes in high-pressure applications, we must look at the material itself. We use grades like 304, 316, and 316L. These materials fight rust and acid. However, the structure of the pipe helps the material do its job. In a chemical plant, fluids flow through the pipes constantly. If the pipe has a weld seam, the fluid hits that seam. The texture is slightly different there. This can cause turbulence. Turbulence speeds up corrosion. It is like a river eroding a bank. Seamless pipes are smooth inside. The fluid flows without hitting bumps. This reduces the speed of corrosion. Temperature is another big factor. We supply pipes for power plants and LNG ships. In power plants, steam gets very hot. Seamless tubes expand evenly. They do not crack under heat stress. In LNG ships, the gas is -162°C. Normal steel becomes brittle like glass. Our austenitic stainless steel stays tough. I have seen welded pipes fail in heat exchangers. The weld expands at a different rate than the rest of the tube. This causes cracks. Seamless tubes are uniform. They expand and contract as one unit. This makes them perfect for heat exchangers and condensers. You avoid the risk of mixing fluids due to cracks. Here is a breakdown of common material grades we use and where they fit best:

· TP316/316L: Adds Molybdenum. Great for saltwater and chlorides. We ship this for marine projects.

· TP310S: High heat resistance. Best for furnace tubes and burners.

· Duplex (2205): Double the strength. Used in very aggressive oil and gas environments.

Inaccurate pipe dimensions lead to installation headaches and wasted time. Frequent maintenance kills your budget. You want a "install it and forget it" solution. Seamless manufacturing allows for tighter tolerances and thicker walls for small diameters. While the initial cost is higher, the reduced maintenance and longer lifespan provide better value, highlighting the economic benefits of seamless stainless steel tubes in high-pressure applications. As a supplier, I often discuss "Total Cost of Ownership" with buyers. You might look at the price list and see seamless pipes cost more than welded ones. This is true. The production process is longer and uses more energy. But you need to look at the next 10 or 20 years. We produce seamless tubes using cold drawing or cold rolling. This gives us high precision. The outer diameter and wall thickness are very exact. When your team installs these pipes, they fit perfectly. You do not waste time cutting and adjusting. Time on the construction site is money. Also, think about the wall thickness. With welded pipes, it is hard to make thick walls on small tubes. Seamless technology can do this easily. This is vital for high-pressure hydraulic lines or instrument tubing. These small tubes carry huge pressure. They need thick walls. Hygiene is another point for value. In food or drug factories, bacteria hide in rough spots. The weld bead in a pipe is a hiding spot. Seamless pipes are smooth. They are easy to clean. This saves money on cleaning chemicals and reduces the risk of contaminated product. Finally, consider replacement costs. If a welded pipe fails after 5 years, you have to shut down the plant. You lose production. You pay for labor. You pay for new parts. A seamless pipe might last 15 or 20 years in the same spot. The extra money you pay at the start is small compared to the cost of a shutdown. At Centerway Steel, we help you calculate this. We want you to have the best result for your project, not just the cheapest quote today. Comparison of Long-term Value:

1. Installation: Faster fit-up due to precise dimensions.

2. Maintenance: Fewer inspections needed on weld seams (because there are none).

3. Cleaning: Lower cost for hygienic systems.

4. Lifespan: typically 1.5x to 2x longer in harsh conditions compared to welded alternatives.

Seamless stainless steel tubes offer unmatched safety, corrosion resistance, and long-term value for high-pressure systems. They are the smart investment for critical infrastructure projects requiring durability and reliability.