A cold drawn seamless tube is a high-precision steel pipe manufactured through a cold working process, offering superior dimensional accuracy, smooth surface finish, and enhanced mechanical properties. Widely used in hydraulic systems, automotive components, and aerospace applications, cold drawn seamless tubes provide reliability where strength and precision are critical.

This article explains the manufacturing process, key benefits, and why industries prefer cold drawn seamless tubes over other alternatives.

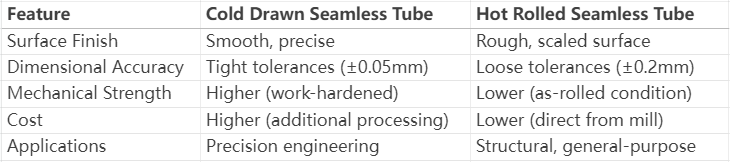

A cold drawn seamless tube is produced by drawing a hot-rolled seamless tube through a die at room temperature, reducing its diameter and wall thickness while improving its mechanical properties. Unlike welded pipes, seamless tubes have no joints, making them stronger and more resistant to pressure and corrosion.

✔ High dimensional accuracy (tight tolerances)

✔ Smooth internal & external surface (reduced friction)

✔ Enhanced strength & hardness (due to cold working)

✔ Uniform grain structure (better performance under stress)

· A solid steel billet is heated and pierced to form a hollow shell.

· The shell is rolled and stretched into a larger-diameter seamless tube.

The hot-rolled tube undergoes cold drawing for precision:

1. Pickling & Lubrication – Removes scale and applies lubricant.

2. Cold Drawing – The tube is pulled through a die, reducing its diameter.

3. Annealing (Optional) – Heat treatment relieves stress and improves ductility.

4. Finishing – Cutting, straightening, and surface treatment (polishing, coating).

· Ultrasonic Testing (UT) – Detects internal flaws.

· Eddy Current Testing – Checks surface defects.

· Dimensional Inspection – Ensures precise OD (outer diameter) and WT (wall thickness).

· Cold working increases tensile strength and hardness.

· Ideal for high-pressure applications (hydraulic cylinders, fuel injection systems).

· Smoother than hot-rolled tubes, reducing friction in fluid systems.

· Requires less machining before use.

· Precision-fit applications (bearings, pistons, instrumentation).

· Reduces material waste in machining.

· Uniform structure resists cracking under cyclic loads.

· Preferred in automotive and aerospace components.

· Available in carbon steel (1020, 1045), alloy steel (4130, 4140), and stainless steel (304, 316).

Due to their precision and strength, cold drawn seamless tubes are used in:

✅ Hydraulic & Pneumatic Systems (Cylinder barrels, pressure tubes)

✅ Automotive Components (Fuel injectors, shock absorbers, drive shafts)

✅ Aerospace & Defense (Landing gear, hydraulic lines)

✅ Precision Machinery (Bearings, rollers, instrumentation)

✅ Oil & Gas Equipment (Downhole tools, instrumentation tubing)

Cold drawn seamless tubes offer unmatched precision, strength, and surface quality, making them essential for high-performance industries. Whether for hydraulic systems, automotive parts, or aerospace components, their superior mechanical properties justify the higher cost in critical applications.

For engineers and buyers, selecting the right cold drawn seamless tube involves considering material grade, dimensional tolerances, and post-drawing treatments (annealing, polishing). Always verify certifications (ASTM A519, DIN 2391) to ensure compliance with industry standards.