When it comes to producing high-strength, high-precision steel tubing, few methods can match the cold drawn seamless tube manufacturing process. This advanced production technique is essential in industries such as automotive, aerospace, energy, and hydraulics—where accuracy, durability, and smooth finishes are critical. In this guide, we’ll take a deep dive into how the process works, its advantages, and the key quality considerations to ensure exceptional performance.

The cold drawn seamless tube manufacturing process is a metal-forming method used to produce seamless steel tubes with tight dimensional tolerances and superior surface finishes. Unlike welded tubes, seamless tubes are formed without a seam, eliminating weak points and ensuring uniform strength across the entire length.

The term “cold drawn” refers to the process of reducing the tube’s diameter and wall thickness at room temperature (as opposed to hot rolling). This cold working enhances mechanical properties and dimensional precision, making these tubes ideal for high-pressure and high-performance applications.

· Superior Dimensional Accuracy – Ideal for applications requiring tight tolerances.

· Enhanced Mechanical Properties – Increased tensile strength and hardness.

· Excellent Surface Finish – Smooth surfaces that reduce friction and wear.

· No Weld Seams – Eliminates weak points, ensuring uniform structural integrity.

· Material Versatility – Suitable for carbon steel, alloy steel, stainless steel, and more.

· Automotive: Precision fuel injection lines, shock absorber tubes.

· Aerospace: Hydraulic and pneumatic system tubing.

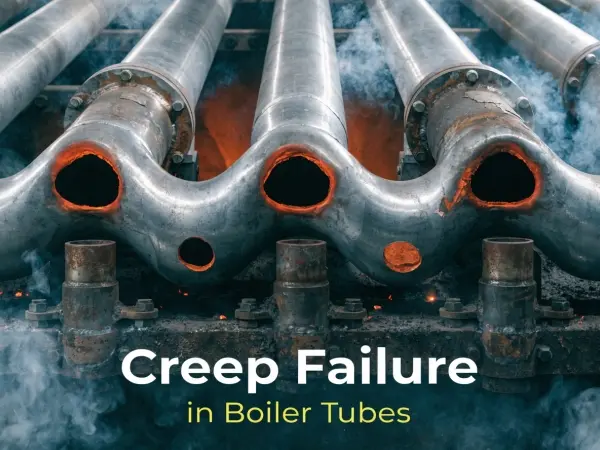

· Energy: Boiler tubes, heat exchanger tubes, and oil & gas piping.

· Machinery: Cylinder tubes, bearing tubes, and mechanical components.

Maintaining high quality requires strict control at every stage:

· Raw Material Certification to ensure chemical composition meets standards.

· Die and Mandrel Maintenance to avoid surface defects.

· Non-Destructive Testing (NDT) to detect internal and external flaws.

· Dimensional Audits to ensure compliance with industry standards like ASTM, EN, or JIS.

The cold drawn seamless tube manufacturing process is a precision-driven method that transforms raw steel into high-performance tubing for demanding industries. By understanding the process steps, benefits, and quality control measures, manufacturers and buyers alike can make informed decisions that ensure reliability, safety, and cost-effectiveness.

For businesses seeking top-tier tubing, choosing a supplier with expertise in cold drawing is key—because when every millimeter matters, precision is everything.