In industries where strength, durability, and pressure resistance are critical, heavy wall seamless pipe plays a crucial role. This specialized type of piping is designed to withstand extreme conditions and is widely used in sectors such as oil and gas, power generation, chemical processing, and heavy machinery. But what exactly is a heavy wall seamless pipe, and why is it so important? In this article, we’ll explore its definition, key properties, manufacturing process, and common applications.

A heavy wall seamless pipe is a type of steel pipe with a thicker-than-standard wall thickness and no welded seam. Unlike welded pipes, which are made by rolling and welding steel sheets, seamless pipes are manufactured through a solid billet extrusion process. This gives them superior mechanical strength, pressure tolerance, and uniformity.

The term "heavy wall" refers to the pipe’s increased wall thickness relative to its diameter, usually required for high-pressure or high-load applications. Common materials include carbon steel, alloy steel, and stainless steel, depending on the intended environment and use.

Heavy wall seamless pipe is vital in a variety of industrial applications, including:

In both upstream and downstream operations, these pipes transport crude oil, natural gas, and drilling muds under extreme pressure and corrosive conditions. They're commonly used in pipelines, well casings, and subsea applications.

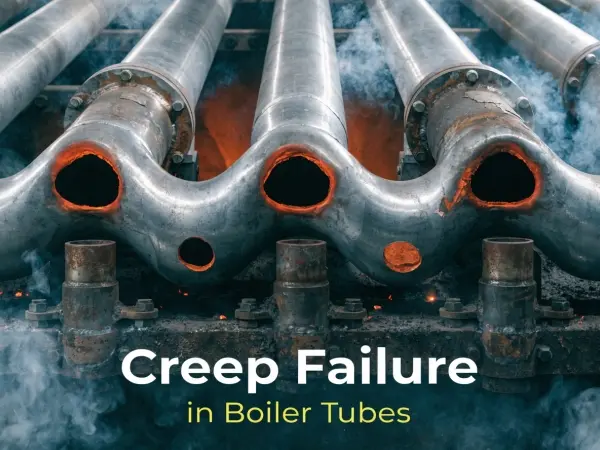

Power plants, especially nuclear and thermal facilities, rely on heavy wall seamless pipes for boiler tubes, heat exchangers, and high-temperature steam lines.

In environments where exposure to aggressive chemicals and high pressures is frequent, seamless pipes offer safe and reliable performance.

Heavy machinery manufacturers use heavy wall seamless pipes for hydraulic cylinders, rollers, and precision components that require high strength and fatigue resistance.

Due to their corrosion resistance and structural strength, these pipes are ideal for offshore platforms, underwater pipelines, and shipbuilding.

To ensure quality and safety, heavy wall seamless pipes are often produced according to recognized standards such as:

· ASTM A106 / A53 – For carbon steel pipe in high-temperature services

· ASTM A335 – For seamless ferritic alloy steel pipe

· ASME B36.10 / B36.19 – For wall thickness and dimensions

Always consult your engineering team or supplier to confirm the appropriate grade and spec for your application.

A heavy wall seamless pipe is not just another steel tube — it's an engineered solution designed to perform under the most demanding conditions. Whether you're managing an oil refinery, a chemical plant, or a hydroelectric facility, choosing the right pipe can directly impact the safety, efficiency, and longevity of your operation.

If you're sourcing heavy wall seamless pipes or need help selecting the right specification, contact our team of experts for technical support and pricing options.