If you work in construction, oil & gas, power generation, or any heavy industry, you’ve probably faced this question: is seamless pipe stronger than welded? Choosing the wrong type of pipe can lead to costly repairs, safety issues, and even project delays.

This article breaks down the science, advantages, and real-world applications of seamless and welded pipes—and shows you how to choose the right one for your project.

Seamless pipes are manufactured from solid steel billets that are heated and pierced to form a hollow tube. Since there is no weld seam, the pipe has uniform strength and a flawless surface.

· High strength and durability – no weak weld line

· Superior pressure resistance – ideal for high-pressure systems

· Better corrosion resistance – fewer points for corrosion to start

· Reliable performance – trusted in critical industries like aerospace and oil refining

Welded pipes are made by rolling steel sheets into cylindrical shapes and welding the seam. Modern technologies such as electric resistance welding (ERW) and submerged arc welding (SAW) have improved the quality and consistency of welded pipes significantly.

· More affordable – cost-effective for large projects

· Wider size availability – can be produced in large diameters

· Smooth surface finish – easier to coat or paint

· Eco-friendly production – less raw material waste compared to seamless manufacturing

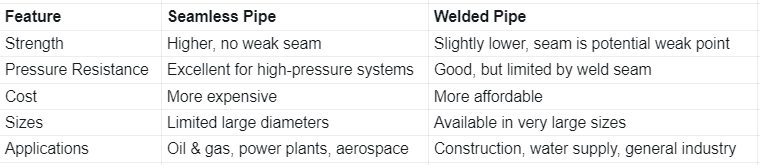

The direct answer is yes, seamless pipe is typically stronger than welded pipe. The absence of a weld seam means there is no structural weak point, making seamless pipes better for high-pressure, high-temperature, and highly corrosive applications.

That said, thanks to advanced welding technologies, welded pipes are still incredibly strong and reliable for most structural and low-to-medium pressure applications.

o Oil and gas exploration

o Power plants (boilers, heat exchangers)

o Chemical and petrochemical industries

o High-pressure pipelines

o Construction and infrastructure

o Water distribution systems

o Low-to-medium pressure pipelines

o Structural applications (scaffolding, supports)

1. Is seamless pipe stronger than welded for all applications?

Not always. While seamless pipe is structurally stronger, welded pipe can still perform well in low-to-medium pressure and structural uses.

2. Which is more cost-effective: seamless or welded pipe?

Welded pipe is usually more affordable, especially for larger diameters and bulk orders.

3. Do seamless pipes last longer?

In high-pressure and high-temperature environments, yes. Seamless pipes generally provide longer service life.

4. Can welded pipes replace seamless pipes?

In many industries, yes. But in critical systems where safety is paramount, seamless is the preferred choice.

So, is seamless pipe stronger than welded? The answer is a clear yes—seamless pipes outperform welded ones in terms of strength, pressure resistance, and reliability. However, if your project is cost-sensitive and doesn’t demand maximum strength, welded pipes remain an excellent choice.

Pro Tip: If your project requires strong, high-quality seamless pipe, we’ve got you covered. Our seamless pipes are engineered for maximum durability, pressure resistance, and long-term performance. Contact us today, and we’ll help you find the product that matches your exact project requirements.